|

| September 08, 2020 | Volume 16 Issue 34 |

Electrical/Electronic News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Board-level EMI shielding: DIY in minutes

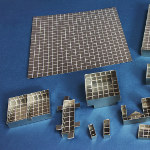

ProtoShield sheets from Tech-Etch are depth-etched with a checkerboard pattern for folding, so they can be easily formed into many diverse configurations. In the product-development stage, fully functional shields can be created in minutes with just a pair of scissors and a straight edge for folding. Offered in two sizes: standard (.25-in. squares) and metric (5-mm squares). Both versions are solderable and corrosion resistant due to nickel silver material. Shield prototypes can be directly soldered to the board, or shield clips can be used for easy mounting. Samples available.

ProtoShield sheets from Tech-Etch are depth-etched with a checkerboard pattern for folding, so they can be easily formed into many diverse configurations. In the product-development stage, fully functional shields can be created in minutes with just a pair of scissors and a straight edge for folding. Offered in two sizes: standard (.25-in. squares) and metric (5-mm squares). Both versions are solderable and corrosion resistant due to nickel silver material. Shield prototypes can be directly soldered to the board, or shield clips can be used for easy mounting. Samples available.

Learn more.

Isolated probing tech for fast-switching power device testing

Keysight Technologies has developed an optically isolated differential probing family dedicated to enhancing efficiency and performance testing of fast-switching devices such as wide-bandgap GaN and SiC semiconductors. Validation of floating half-bridge and full-bridge architectures commonly used in power conversion, motor drives, and inverters requires measurement of small differential signals riding on high common-mode voltages. This measurement can be challenging due to voltage source fluctuations relative to ground, noise interference, and safety concerns.

Keysight Technologies has developed an optically isolated differential probing family dedicated to enhancing efficiency and performance testing of fast-switching devices such as wide-bandgap GaN and SiC semiconductors. Validation of floating half-bridge and full-bridge architectures commonly used in power conversion, motor drives, and inverters requires measurement of small differential signals riding on high common-mode voltages. This measurement can be challenging due to voltage source fluctuations relative to ground, noise interference, and safety concerns.

Learn more.

Protect sensitive electronics in explosive environments with new aluminum ATEX Cabinet Cooler Systems

EXAIR's ATEX Cabinet Cooler® Systems deliver a powerful and affordable solution for keeping electrical enclosures cool in hazardous ATEX classified areas -- and they're now available in durable aluminum construction. Engineered for use in Zones 2 and 22, these coolers are UL tested, CE compliant, and meet stringent ATEX standards for purged and pressurized enclosures. With cooling capacities up to 5,600 Btu/Hr., ATEX Cabinet Coolers are ideal for preventing overheating in electrical cabinets. EXAIR offers a comprehensive lineup of systems.

EXAIR's ATEX Cabinet Cooler® Systems deliver a powerful and affordable solution for keeping electrical enclosures cool in hazardous ATEX classified areas -- and they're now available in durable aluminum construction. Engineered for use in Zones 2 and 22, these coolers are UL tested, CE compliant, and meet stringent ATEX standards for purged and pressurized enclosures. With cooling capacities up to 5,600 Btu/Hr., ATEX Cabinet Coolers are ideal for preventing overheating in electrical cabinets. EXAIR offers a comprehensive lineup of systems.

Learn more.

PLC handbook chock full of must-know information

Automation-Direct's Practical Guide to Program-mable Logic Controllers Handbook has been improved with tons of new need-to-know info, making it a more comprehensive guide to the world of PLCs. Besides covering the basics of PLC history, PLC hardware, and PLC software, this guide takes you deeper into the ever-changing world of PLC communication, the importance of feedback loops, cyber security, and many other areas that are a must-know for any PLC novice or seasoned automation professional.

Automation-Direct's Practical Guide to Program-mable Logic Controllers Handbook has been improved with tons of new need-to-know info, making it a more comprehensive guide to the world of PLCs. Besides covering the basics of PLC history, PLC hardware, and PLC software, this guide takes you deeper into the ever-changing world of PLC communication, the importance of feedback loops, cyber security, and many other areas that are a must-know for any PLC novice or seasoned automation professional.

Get this great resource today.

Haptic feedback prototyping kit from TDK

Get your customers to feel the difference your products make. TDK has released a development starter kit for fast haptics prototyping. It gives mechanical designers and engineers first impressions of the haptic feedback using PowerHap piezo actuators, shows how the mechanical integration works, and provides a reference design. Applications include automotive, displays and tablets, household appliances, vending machines, game controllers, industrial equipment, and medical devices.

Get your customers to feel the difference your products make. TDK has released a development starter kit for fast haptics prototyping. It gives mechanical designers and engineers first impressions of the haptic feedback using PowerHap piezo actuators, shows how the mechanical integration works, and provides a reference design. Applications include automotive, displays and tablets, household appliances, vending machines, game controllers, industrial equipment, and medical devices.

Learn more.

Mini ESD preset torque screwdriver

Need precision fastening with ESD protection at the smallest torque levels? Mountz has you covered. The new FG Mini ESD Preset Torque Screwdriver is built for low-torque, high-precision tasks. Its compact design makes it ideal for tight spaces and small fasteners, while delivering the same reliable control and ESD protection users have come to expect from Mountz. Two models available: FG25z (3 to 25 ozf.in, 2 to 17.7 cN-m) and FG50z (20 to 50 ozf.in, 14.1 to 35.3 cN-m).

Need precision fastening with ESD protection at the smallest torque levels? Mountz has you covered. The new FG Mini ESD Preset Torque Screwdriver is built for low-torque, high-precision tasks. Its compact design makes it ideal for tight spaces and small fasteners, while delivering the same reliable control and ESD protection users have come to expect from Mountz. Two models available: FG25z (3 to 25 ozf.in, 2 to 17.7 cN-m) and FG50z (20 to 50 ozf.in, 14.1 to 35.3 cN-m).

Learn more.

Laumas load cells and electronics from AutomationDirect

Automation-Direct has added Laumas precision-engineered load cells, transmitters, and accessories that deliver reliable performance in industrial weighing and force measurement applications. The FCAL series high-precision bending beam load cells are ideal for low- to mid-capacity systems. CTL series load cells are designed for both tension and compression, with excellent linearity. The CBL series low-profile compression load cells are perfect for space-limited applications. Laumas load cell transmitters are available too for precise monitoring and control. Very good pricing.

Automation-Direct has added Laumas precision-engineered load cells, transmitters, and accessories that deliver reliable performance in industrial weighing and force measurement applications. The FCAL series high-precision bending beam load cells are ideal for low- to mid-capacity systems. CTL series load cells are designed for both tension and compression, with excellent linearity. The CBL series low-profile compression load cells are perfect for space-limited applications. Laumas load cell transmitters are available too for precise monitoring and control. Very good pricing.

Learn more.

Engineer's Toolbox: What is ground loop feedback?

Improper grounding can create problems in data logging, data acquisition, and measurement and control systems. One of the most common problems is known as ground loop feedback. Experts at CAS DataLoggers run through five ways to eliminate this problem.

Improper grounding can create problems in data logging, data acquisition, and measurement and control systems. One of the most common problems is known as ground loop feedback. Experts at CAS DataLoggers run through five ways to eliminate this problem.

Read the full article.

What is a braking resistor?

According to Automation-Direct, "Braking resistors don't actually provide braking directly -- rather, they allow a drive to stop a loaded motor faster." Why is this important? Protect your AC or DC drive system from regenerative voltage that can create an over-voltage fault on the drive -- especially with high inertial loads or rapid deceleration.

According to Automation-Direct, "Braking resistors don't actually provide braking directly -- rather, they allow a drive to stop a loaded motor faster." Why is this important? Protect your AC or DC drive system from regenerative voltage that can create an over-voltage fault on the drive -- especially with high inertial loads or rapid deceleration.

View the video.

New Digital Static Meter: Precise measurement, easy use

Static electricity isn't just a nuisance; it's a serious threat to manufacturing efficiency, product integrity, and workplace safety. Unchecked static can lead to costly downtime, product defects, material jams, and even hazardous shocks to employees. If static is interfering with your processes, EXAIR's upgraded Model 7905 Digital Static Meter offers an essential first step in identifying and eliminating the problem. With just the press of a button, this easy-to-use, handheld device pinpoints the highest voltage areas in your facility, helping you diagnose static issues before they become a problem.

Static electricity isn't just a nuisance; it's a serious threat to manufacturing efficiency, product integrity, and workplace safety. Unchecked static can lead to costly downtime, product defects, material jams, and even hazardous shocks to employees. If static is interfering with your processes, EXAIR's upgraded Model 7905 Digital Static Meter offers an essential first step in identifying and eliminating the problem. With just the press of a button, this easy-to-use, handheld device pinpoints the highest voltage areas in your facility, helping you diagnose static issues before they become a problem.

Learn more.

New laser cutting modulating strategy tested with Mikrotron high-speed camera

Modulating a laser beam's intensity distribution optimizes energy delivery to the process zone, resulting in better cutting speed, cut edge quality, and cut kerf geometry. Scientists in Belgium have come up with a new method that they say produces better cutting results.

Modulating a laser beam's intensity distribution optimizes energy delivery to the process zone, resulting in better cutting speed, cut edge quality, and cut kerf geometry. Scientists in Belgium have come up with a new method that they say produces better cutting results.

Read the full article.

All-in-one embedded PLC based on Raspberry Pi 4 -- build control applications

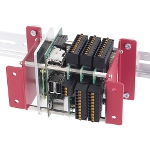

The new PLC CPI-PS10CM4 from Contec Co. is a compact embedded programmable logic controller (PLC) that is loaded with CODESYS, the world's most widely used software PLC. This product uses Contec's original single-board computer, which is based on Raspberry Pi's latest embedded module, the Compute Module 4 (CM4). By using the wide range of peripheral devices for Raspberry Pi, such as Contec's CPI Series, you can build various control applications in a PLC language that complies with the IEC 61131-3 international standard.

The new PLC CPI-PS10CM4 from Contec Co. is a compact embedded programmable logic controller (PLC) that is loaded with CODESYS, the world's most widely used software PLC. This product uses Contec's original single-board computer, which is based on Raspberry Pi's latest embedded module, the Compute Module 4 (CM4). By using the wide range of peripheral devices for Raspberry Pi, such as Contec's CPI Series, you can build various control applications in a PLC language that complies with the IEC 61131-3 international standard.

Learn more.

Torque sensors for fastening applications and more

Saelig Company has introduced the Sensor Technology SGR525/526 Series Torque Sensors to provide precision torque monitoring that is critical for performance and safety. The square drive design (for applications with non-cylindrical shafts) allows for seamless integration into power tools, test rigs, industrial machinery, and precision fastening applications, ensuring superior torque measurement without the need for additional adapters or modifications. The SGR525 offers torque measurement only, while the SGR526 provides torque, speed, and power measurement using a 360-pulse-per-revolution encoder. Industries include automotive, aerospace, manufacturing, and research and development.

Saelig Company has introduced the Sensor Technology SGR525/526 Series Torque Sensors to provide precision torque monitoring that is critical for performance and safety. The square drive design (for applications with non-cylindrical shafts) allows for seamless integration into power tools, test rigs, industrial machinery, and precision fastening applications, ensuring superior torque measurement without the need for additional adapters or modifications. The SGR525 offers torque measurement only, while the SGR526 provides torque, speed, and power measurement using a 360-pulse-per-revolution encoder. Industries include automotive, aerospace, manufacturing, and research and development.

Learn more.

Wide-angle camera optimized for larger, faster conveyor belts

Wider conveyor belts operating at higher speeds are now commonplace in modern logistics. To keep up, SVS-Vistek is offering a cost-effective alternative to multi-camera systems with its fxo901CXGE 10-GigE color camera featuring the Sony IMX901-AQR wide-aspect global shutter 16.4-megapixel CMOS sensor. Unlike standard cameras, this unit captures targets in a wide field of view while maintaining high resolutions. The 4:1 horizontal aspect ratio allows one fxo901CXGE to replace an entire multi-camera system, removing the need for image synchronization.

Wider conveyor belts operating at higher speeds are now commonplace in modern logistics. To keep up, SVS-Vistek is offering a cost-effective alternative to multi-camera systems with its fxo901CXGE 10-GigE color camera featuring the Sony IMX901-AQR wide-aspect global shutter 16.4-megapixel CMOS sensor. Unlike standard cameras, this unit captures targets in a wide field of view while maintaining high resolutions. The 4:1 horizontal aspect ratio allows one fxo901CXGE to replace an entire multi-camera system, removing the need for image synchronization.

Learn more.

Handheld thermal imager cuts diagnostic time

The FLIR TG268 is a next-generation thermal imager that provides professionals in the utility, manufacturing, electrical, automotive, and industrial sectors with a lightweight, handheld, affordable condition monitoring tool. Latest enhancements include higher temperature ranges, improved resolution, and larger data storage capacity. Go beyond the restrictions of single-spot IR thermometers to view and evaluate hot and cold spots that may signify potentially dangerous issues. Accurately measure temps from -25 to 400 C. Native thermal images improved with Super Resolution upscaling.

The FLIR TG268 is a next-generation thermal imager that provides professionals in the utility, manufacturing, electrical, automotive, and industrial sectors with a lightweight, handheld, affordable condition monitoring tool. Latest enhancements include higher temperature ranges, improved resolution, and larger data storage capacity. Go beyond the restrictions of single-spot IR thermometers to view and evaluate hot and cold spots that may signify potentially dangerous issues. Accurately measure temps from -25 to 400 C. Native thermal images improved with Super Resolution upscaling.

Learn more.

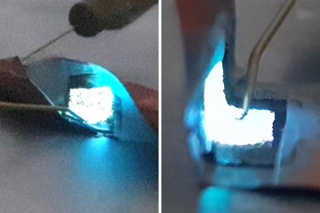

Bend it, cut it, shape it: Flexible micro LEDs may reshape future of wearable technology

Newly developed flexible micro LEDs can be twisted (left) or folded (right). The LEDs, which can be peeled off and stuck to almost any surface, could help pave the way for the next generation of wearable technology. [Credit: The University of Texas at Dallas]

University of Texas at Dallas researchers and their international colleagues have developed a method to create micro LEDs that can be folded, twisted, cut, and stuck to different surfaces.

The research, published online in June in the journal Science Advances, helps pave the way for the next generation of flexible, wearable technology.

Used in products ranging from brake lights to billboards, LEDs are ideal components for backlighting and displays in electronic devices because they are lightweight, thin, energy efficient, and visible in different types of lighting. Micro LEDs, which can be as small as 2 micrometers and bundled to be any size, provide higher resolution than other LEDs. Their size makes them a good fit for small devices such as smart watches, but they can be bundled to work in flat-screen TVs and other larger displays. LEDs of all sizes, however, are brittle and typically can only be used on flat surfaces.

The researchers' new micro LEDs aim to fill a demand for bendable, wearable electronics.

"The biggest benefit of this research is that we have created a detachable LED that can be attached to almost anything," said Dr. Moon Kim, Louis Beecherl Jr. Distinguished Professor of materials science and engineering at UT Dallas and a corresponding author of the study. "You can transfer it onto your clothing or even rubber -- that was the main idea. It can survive even if you wrinkle it. If you cut it, you can use half of the LED."

Researchers in the Erik Jonsson School of Engineering and Computer Science and the School of Natural Sciences and Mathematics helped develop the flexible LED through a technique called remote epitaxy, which involves growing a thin layer of LED crystals on the surface of a sapphire crystal wafer, or substrate.

Typically, the LED would remain on the wafer. To make it detachable, researchers added a nonstick layer to the substrate, which acts similarly to the way parchment paper protects a baking sheet and allows for the easy removal of cookies, for instance. The added layer, made of a one-atom-thick sheet of carbon called graphene, prevents the new layer of LED crystals from sticking to the wafer.

"The graphene does not form chemical bonds with the LED material, so it adds a layer that allows us to peel the LEDs from the wafer and stick them to any surface," said Kim, who oversaw the physical analysis of the LEDs using an atomic resolution scanning/transmission electron microscope at UT Dallas' Nano Characterization Facility.

Colleagues in South Korea carried out laboratory tests of LEDs by adhering them to curved surfaces, as well as to materials that were subsequently twisted, bent, and crumpled. In another demonstration, they adhered an LED to the legs of a Lego minifigure with different leg positions.

Bending and cutting do not affect the quality or electronic properties of the LED, Kim said.

The bendy LEDs have a variety of possible uses, including flexible lighting, clothing, and wearable biomedical devices. From a manufacturing perspective, the fabrication technique offers another advantage: Because the LED can be removed without breaking the underlying wafer substrate, the wafer can be used repeatedly.

"You can use one substrate many times, and it will have the same functionality," Kim said.

In ongoing studies, the researchers also are applying the fabrication technique to other types of materials.

"It's very exciting; this method is not limited to one type of material," Kim said. "It's open to all kinds of materials."

Source: University of Texas at Dallas

Published September 2020

Rate this article

View our terms of use and privacy policy