|

| July 09, 2024 | Volume 20 Issue 26 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

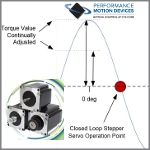

How to maximize and optimize stepper motor control

Engineers from Performance Motion Devices take a comprehensive look at how to control two-phase stepper motors, beginning with the basics (operations, strengths and weaknesses) and moving on to traditional and updated advanced techniques for control including closed loop. A very thorough presentation.

Engineers from Performance Motion Devices take a comprehensive look at how to control two-phase stepper motors, beginning with the basics (operations, strengths and weaknesses) and moving on to traditional and updated advanced techniques for control including closed loop. A very thorough presentation.

Read this informative Performance Motion Devices article.

Ergoswiss table lifting systems from AutomationDirect

Automation-Direct has added the new SQ series table lifting systems from Ergoswiss. These lifting systems use electrically driven columns that allow the operator to reposition the height of a worktable, conveyor, etc. to meet specific requirements. In doing so, the operator can perform their tasks in a more comfortable working posture, helping to reduce work-related injuries. These systems are all electric (no hydraulic mess or manual hand cranks), and each lifting column features a housed motor and screw drive to perform the needed height adjustments.

Automation-Direct has added the new SQ series table lifting systems from Ergoswiss. These lifting systems use electrically driven columns that allow the operator to reposition the height of a worktable, conveyor, etc. to meet specific requirements. In doing so, the operator can perform their tasks in a more comfortable working posture, helping to reduce work-related injuries. These systems are all electric (no hydraulic mess or manual hand cranks), and each lifting column features a housed motor and screw drive to perform the needed height adjustments.

Learn more.

Compact linear voice coil servo motor with built-in shaft and bearing

![]() The GVCM-032-025-02M Linear Voice Coil Servo Motor is the first of a new series of non-commutated, brushless linear servo motors from Moticont. This clean and quiet unit has a 12.7-mm stroke with built-in shaft and bearing, a continuous high-force-to-size ratio of 9.3 N (2.1 lb), and 29.3 N (6.6 lb) of peak force at a 10% duty cycle. Features include: high reliability, high speed, zero cogging, high acceleration/deceleration, and, when used in a servo loop, very high accuracy and repeatability. An ideal choice for: haptic feedback, medical devices, laser machining and drilling, work holding and clamping, scanners, optical focusing, testing, sorting, and assembly.

The GVCM-032-025-02M Linear Voice Coil Servo Motor is the first of a new series of non-commutated, brushless linear servo motors from Moticont. This clean and quiet unit has a 12.7-mm stroke with built-in shaft and bearing, a continuous high-force-to-size ratio of 9.3 N (2.1 lb), and 29.3 N (6.6 lb) of peak force at a 10% duty cycle. Features include: high reliability, high speed, zero cogging, high acceleration/deceleration, and, when used in a servo loop, very high accuracy and repeatability. An ideal choice for: haptic feedback, medical devices, laser machining and drilling, work holding and clamping, scanners, optical focusing, testing, sorting, and assembly.

Learn more.

Optical rotary encoders: Close the stepper motor linear actuator feedback loop

With the help of a motion controller and a stepper driver, all stepper motor linear actuators can be programmed to position a load to a precise location. However, standard configurations do not provide a feedback mechanism that tells the operator whether the move is completed or not. Adding an encoder can be an effective and simple solution to get real-time motion feedback about your application.

With the help of a motion controller and a stepper driver, all stepper motor linear actuators can be programmed to position a load to a precise location. However, standard configurations do not provide a feedback mechanism that tells the operator whether the move is completed or not. Adding an encoder can be an effective and simple solution to get real-time motion feedback about your application.

Read this informative Thomson article.

Overhead conveyor drives for automotive, food processing

Overhead conveyor drives from NORD DRIVE-SYSTEMS are engineered with long-lasting performance and durability in mind. They feature high-quality components, heavy-duty construction, and an output mounting flange and shaft for easy drop-in replacement of industry-standard footprints. They are an ideal solution for meat and poultry processing, automotive assembly, and other manufacturing systems where utilization of vertical space is required. Lots of options and many more features.

Overhead conveyor drives from NORD DRIVE-SYSTEMS are engineered with long-lasting performance and durability in mind. They feature high-quality components, heavy-duty construction, and an output mounting flange and shaft for easy drop-in replacement of industry-standard footprints. They are an ideal solution for meat and poultry processing, automotive assembly, and other manufacturing systems where utilization of vertical space is required. Lots of options and many more features.

Learn more.

New micro motor controller elevates precision, speed, and torque management

maxon, a leader in DC motor and drive solutions, has unveiled its latest innovation: the ESCON 2 controller. This advanced speed and current controller, designed for micro motors, significantly enhances control precision. The ESCON 2, suitable for brushed and brushless DC motors up to 1,800 W continuous duty, is engineered for seamless OEM integration into customer systems. Enhanced control features include field-oriented control (FOC), acceleration, and velocity feed-forward capabilities. Supports 4-quadrant operation. Lots more features. Available from Electromate.

maxon, a leader in DC motor and drive solutions, has unveiled its latest innovation: the ESCON 2 controller. This advanced speed and current controller, designed for micro motors, significantly enhances control precision. The ESCON 2, suitable for brushed and brushless DC motors up to 1,800 W continuous duty, is engineered for seamless OEM integration into customer systems. Enhanced control features include field-oriented control (FOC), acceleration, and velocity feed-forward capabilities. Supports 4-quadrant operation. Lots more features. Available from Electromate.

Learn more and get all the specs.

Next-gen motor for pump and fan applications

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

Learn more.

Deep learning-based part detection for machine tending cobots: Universal Robots at IMTS

Universal Robots, the pioneer of collaborative robotics, is set to unveil a new AI-powered machine tending solution at IMTS, enabling faster batch changeovers by eliminating the need for fixtures. Additionally, the company will showcase advanced cobot applications for welding, finishing, part feeding, and laser marking. Lots of useful tech here.

Universal Robots, the pioneer of collaborative robotics, is set to unveil a new AI-powered machine tending solution at IMTS, enabling faster batch changeovers by eliminating the need for fixtures. Additionally, the company will showcase advanced cobot applications for welding, finishing, part feeding, and laser marking. Lots of useful tech here.

Read the full article.

Why air bearings are used to test satellites

The number of active satellites in space keeps growing, with more than 10,000 active satellites orbiting our planet. Commercial and academic institutions developing these satellites continuously work on improved test systems and methodologies to fully validate their hardware before launch. Learn why PI's 3-DOF spherical air bearing systems are an important part of this process.

The number of active satellites in space keeps growing, with more than 10,000 active satellites orbiting our planet. Commercial and academic institutions developing these satellites continuously work on improved test systems and methodologies to fully validate their hardware before launch. Learn why PI's 3-DOF spherical air bearing systems are an important part of this process.

Read the full article.

8 key advantages of torque motors for advanced applications

Electric torque motors drive loads at low speed without additional mechanical transmission systems like gearboxes or speed reducers. They are known for smooth operation with less vibration and backlash. Learn the key benefits that make them a solid choice for many applications.

Electric torque motors drive loads at low speed without additional mechanical transmission systems like gearboxes or speed reducers. They are known for smooth operation with less vibration and backlash. Learn the key benefits that make them a solid choice for many applications.

View this informative Parker blog.

Gear motors with QR codes for product info

NORD DRIVE-SYSTEMS gear motors now come with a QR code sticker on the unit enabling users to access information almost instantly such as product specs, documentation, and service requests via mobile device. The codes can be scanned using a photo app or QR code app and will bring the user to NORD's digital service webpage, which includes a Documentation Center, Spare Parts Shop, customer portal, and more. QR code stickers are now in use at NORD USA's four facilities in Waunakee, WI; Corona, CA; Charlotte, NC; and McKinney, TX.

NORD DRIVE-SYSTEMS gear motors now come with a QR code sticker on the unit enabling users to access information almost instantly such as product specs, documentation, and service requests via mobile device. The codes can be scanned using a photo app or QR code app and will bring the user to NORD's digital service webpage, which includes a Documentation Center, Spare Parts Shop, customer portal, and more. QR code stickers are now in use at NORD USA's four facilities in Waunakee, WI; Corona, CA; Charlotte, NC; and McKinney, TX.

Learn more.

LM guide actuator with right/left ball screw for symmetrical movement

THK's innovative Type KR-RL Actuator features a driving element that uses right/left threads and enables symmetrical movements with a single motor. Two drive systems are combined into a single package, resulting in a compact overall design. This electric actuator outperforms pneumatic versions by offering precise force control, speed control, a longer life, and energy savings. Applications include gripping, measuring, and positioning for robot hands, screw-tightening machines, cutting equipment, and dispensers.

THK's innovative Type KR-RL Actuator features a driving element that uses right/left threads and enables symmetrical movements with a single motor. Two drive systems are combined into a single package, resulting in a compact overall design. This electric actuator outperforms pneumatic versions by offering precise force control, speed control, a longer life, and energy savings. Applications include gripping, measuring, and positioning for robot hands, screw-tightening machines, cutting equipment, and dispensers.

Learn more.

High-power-density outer-rotor brushless motor

Allied Motion Technologies has released the new KinetiMax High Power Density (HPD) motor series. This outer-rotor brushless motor is designed for high-torque, low-cogging applications like robotics, AGVs, and handheld power tools. With an efficiency rating of over 85% and a high power-to-weight ratio, it's an ideal motor choice for any application where weight and battery life are critical. Available in six frame sizes, with three stack lengths per size and three windings per stack length.

Allied Motion Technologies has released the new KinetiMax High Power Density (HPD) motor series. This outer-rotor brushless motor is designed for high-torque, low-cogging applications like robotics, AGVs, and handheld power tools. With an efficiency rating of over 85% and a high power-to-weight ratio, it's an ideal motor choice for any application where weight and battery life are critical. Available in six frame sizes, with three stack lengths per size and three windings per stack length.

Learn more.

Universal Robots: Seamless integration with Siemens PLCs

Cobot leader Universal Robots has integrated the Standard Robot Command Interface (SRCI) into its software. UR is proud to be among the first cobot vendors to offer this functionality, which is a new standard for robotics manufacturers that aims to create a single interface between PLCs and robots. It will ensure customers a frictionless integration with Siemens Programmable Logic Controllers, since Siemens is the first -- and currently only -- PLC Vendor supporting SRCI in the automation market.

Cobot leader Universal Robots has integrated the Standard Robot Command Interface (SRCI) into its software. UR is proud to be among the first cobot vendors to offer this functionality, which is a new standard for robotics manufacturers that aims to create a single interface between PLCs and robots. It will ensure customers a frictionless integration with Siemens Programmable Logic Controllers, since Siemens is the first -- and currently only -- PLC Vendor supporting SRCI in the automation market.

Learn more.

Multi-axis motion control chipset

The Magellan® MC58000 and MC55000 Motion Control ICs from Performance Motion Devices provide all the advanced motion control required by sophisticated high-precision medical, scientific, automation, industrial, and robotic applications. Available in 1-, 2-, 3-, and 4-axis versions, these programmable devices control brushless DC, DC brush, and step motors and deliver user-selectable profiling modes including S-curve, trapezoidal, velocity contouring, and electronic gearing. High-performance FOC provides high-accuracy, ultra-low noise motor operation.

The Magellan® MC58000 and MC55000 Motion Control ICs from Performance Motion Devices provide all the advanced motion control required by sophisticated high-precision medical, scientific, automation, industrial, and robotic applications. Available in 1-, 2-, 3-, and 4-axis versions, these programmable devices control brushless DC, DC brush, and step motors and deliver user-selectable profiling modes including S-curve, trapezoidal, velocity contouring, and electronic gearing. High-performance FOC provides high-accuracy, ultra-low noise motor operation.

Learn more.

Honda's E-Clutch for motorcycles turns manual bike into automatic -- or not

Honda E-Clutch. [Credit: Image courtesy of Honda]

Honda Motor Co. has released new details about its E-Clutch technology for motorcycles, which it claims is "the world's first automatic clutch control system for a multi-gear manual motorcycle transmission, enabling smooth starting, shifting gears, and stopping without the need for the rider to operate the clutch lever."

E-Clutch could come as an add-on to a new Honda motorcycle or -- maybe sometime in the future -- as an aftermarket add-on system to any bike. It uses electronic control tech to provide instantaneous, fine-tuned clutch control for optimum performance in situations where the driving force changes, such as starting, shifting gears, and stopping, to achieve smooth starting, shifting gears, and stopping more natural than a rider's manual clutch operation.

One of the main benefits of the technology is that it is user-engageable, meaning riders can turn it on or off whenever they see fit. Love riding your bike in the country or on the highway and the feel and control of manual shift for longer trips? Turn E-Clutch off.

VIDEO: Honda E-Clutch structure and control overview. [Credit: Honda]

"Entrusting clutch operation to the Honda E-Clutch system on winding roads allows the rider to concentrate on throttle, brake, and gear-shifting operations, and on controlling motorcycle behavior," says Honda on its website. "And in circuit racing and other sports riding scenarios, in addition to conventional quick-shifter control, the system can also instantly half-clutch to provide control appropriate to the motorcycle state, which can be better than a quick shifter in reducing changes in motorcycle behavior due to gear shifting."

Having the system on when riding in town or a city could be a real plus. Honda says the clutch can be operated "like a normal manual motorcycle gripping the clutch lever, even when the clutch is controlled electronically," allowing the system "to be used by more riders of diverse riding experience and skills, who can concentrate on the fun of riding in more comfort."

VIDEO: Honda E-Clutch technology rider perspective. [Credit: Honda]

Honda says the lightweight and compact system can be installed "without major changes to existing engine layouts." Honda plans to incorporate the E-Clutch into its FUN motorcycle models "over time." The system also looks like it would work as an aftermarket product, but there is no indication right now Honda will offer this.

According to Cycle World, "The E-Clutch uses two electric motors geared together onto a set of reduction gears, all mounted in a pod attached to the clutch cover. ... The reduction gears are connected to sector gears that, in turn, act on the same clutch release shaft that the conventional, bar-mounted clutch lever is connected to (by a cable, in the case of the CB650R). The final sector gear acts on the release shaft via a cam that allows the manual clutch lever on the bar to override the electronic system. So when the electronics are turned off, the clutch operates as a conventional unit."

There is an angle sensor in there, too. Designfax highlights these types of sensors, like those from Novotechnik, a few times a year. Honda has a diagram of the setup on the E-Clutch info page.

Learn more about this technology at https://global.honda/en/tech/Honda_E-Clutch/. Honda has not released a date for the E-Clutch to appear on its own motorcycles.

Sources: Honda, Cycle World

Published July 2024

Rate this article

View our terms of use and privacy policy