|

| October 01, 2024 | Volume 20 Issue 37 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New tiny lasers fill long-standing color gap, promise new applications

Series of visible-light colors generated by a microring resonator. [Credit: Photo by S. Kelley/Courtesy of NIST]

It's not easy making green.

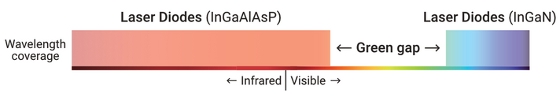

For years, scientists have fabricated small, high-quality lasers that generate red and blue light. However, the method they typically employ -- injecting electric current into semiconductors -- hasn't worked as well in building tiny lasers that emit light at yellow and green wavelengths. Researchers refer to the dearth of stable, miniature lasers in this region of the visible-light spectrum as the "green gap." Filling this gap opens new opportunities in underwater communications, medical treatments, and more.

Green laser pointers have existed for 25 years, but they produce light only in a narrow spectrum of green and are not integrated in chips where they could work together with other devices to perform useful tasks.

Compact laser diodes can emit infrared, red, and blue wavelengths, but are highly inefficient at producing green and yellow wavelengths, a region known as the "green gap." [Credit: Image by S. Kelley/Courtesy of NIST]

Now scientists at the National Institute of Standards and Technology (NIST) have closed the green gap by modifying a tiny optical component: a ring-shaped microresonator, small enough to fit on a chip.

A miniature source of green laser light could improve underwater communication because water is nearly transparent to blue-green wavelengths in most aquatic environments. Other potential applications are in full-color laser projection displays and laser treatment of medical conditions, including diabetic retinopathy, a proliferation of blood vessels in the eye.

Compact lasers in this wavelength range are also important for applications in quantum computing and communication, as they could potentially store data in qubits, the fundamental unit of quantum information. Currently, these quantum applications depend on lasers that are larger in size, weight, and power, limiting their ability to be deployed outside the laboratory.

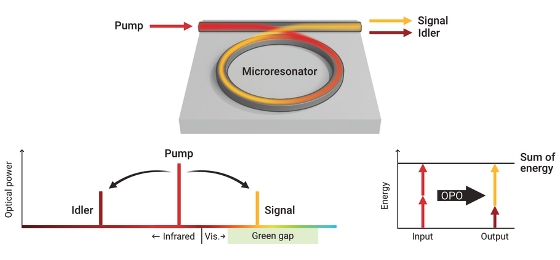

For several years, a team led by Kartik Srinivasan of NIST and the Joint Quantum Institute (JQI), a research partnership between NIST and the University of Maryland, has used microresonators composed of silicon nitride to convert infrared laser light into other colors. When infrared light is pumped into the ring-shaped resonator, the light circles thousands of times until it reaches intensities high enough to interact strongly with the silicon nitride. That interaction, known as an optical parametric oscillation (OPO), produces two new wavelengths of light, called the idler and the signal.

Infrared laser light, known as the pump, is beamed into a ring-shaped microresonator and converted through an optical parametric oscillation into two new wavelengths of light, known as the signal and the idler (top). The signal has a wavelength that lies in the visible range, while the idler has an infrared wavelength that is longer than that of the pump laser. Since energy is conserved, the energy carried by two pump photons must equal the sum of the energy carried by a single photon from each of the two output wavelengths (bottom right). [Credit: Image by S. Kelley/Courtesy of NIST]

In previous studies, the researchers generated a few individual colors of visible laser light. Depending on the dimensions of the microresonator, which determine the colors of light that are generated, scientists produced red, orange, and yellow wavelengths, as well as a wavelength of 560 nanometers, right at the hairy edge between yellow and green light. However, the team could not generate the full complement of yellow and green colors necessary to fill the green gap.

"We didn't want to be good at hitting just a couple of wavelengths," said NIST scientist Yi Sun, a collaborator on the new study. "We wanted to access the entire range of wavelengths in the gap."

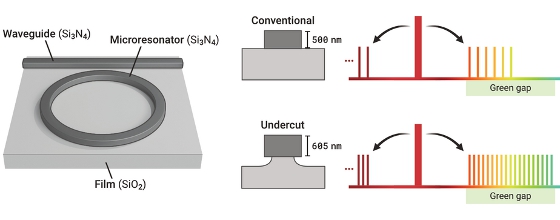

To fill the gap, the team modified the microresonator in two ways. First, the scientists slightly thickened it. By changing its dimensions, the researchers more easily generated light that penetrated deeper into the green gap, to wavelengths as short as 532 nanometers (billionths of a meter). With this extended range, the researchers covered the entire gap.

In addition, the team exposed the microresonator to more air by etching away some of the silicon dioxide layer below it. This had the effect of making the output colors less sensitive to the microring dimensions and the infrared pump wavelength. The lower sensitivity gave the researchers more control in generating slightly different green, yellow, orange, and red wavelengths from their device.

Conventional microresonators (top) are limited in the wavelengths they can produce through OPO. By partially etching away the silicon dioxide film under the microresonator to create an "undercut" and using a thicker layer of silicon nitride (bottom), NIST researchers were able to cover the entire "green gap" spectral range while also improving the density of the generated wavelengths. [Credit: Image by S. Kelley/Courtesy of NIST]

As a result, the researchers found they could create more than 150 distinct wavelengths across the green gap and fine-tune them. "Previously, we could make big changes -- red to orange to yellow to green -- in the laser colors we could generate with OPO, but it was hard to make small adjustments within each of those color bands," Srinivasan noted.

By changing the wavelength of the infrared pump, NIST researchers can generate wavelengths of visible light across the entire green gap. The video at bottom, taken by the researchers, depicts the process. [Credit: Animation photos by S. Kelley/Courtesy of NIST]

The scientists are now working to boost the energy efficiency with which they produce the green-gap laser colors. Currently, the output power is only a few percent of that of the input laser. Better coupling between the input laser and the waveguide that channels the light into the microresonator, along with better methods of extracting the generated light, could significantly improve the efficiency.

The researchers, who include Jordan Stone and Xiyuan Lu from JQI, along with Zhimin Shi from Meta's Reality Labs Research in Redmond, Washington, reported their findings August 21 online in Light: Science and Applications.

Read more NIST news and developments at nist.gov/news-events/news.

Source: NIST

Published October 2024

Rate this article

View our terms of use and privacy policy