|

| November 19, 2024 | Volume 20 Issue 44 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

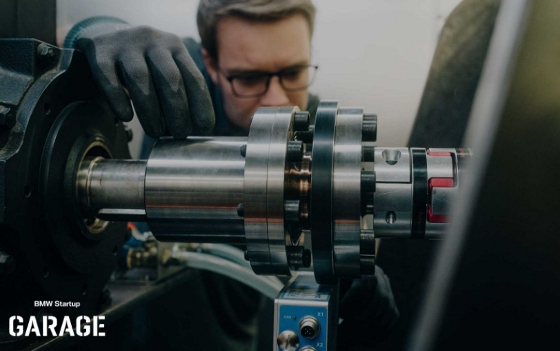

BMW to road-test revolutionary in-wheel drive motor

[Credit: Image by DeepDrive/Courtesy of BMW Group.]

The BMW Startup Garage, a development spinoff of BMW Group, and Munich-based motor developer DeepDrive are set to road-test a revolutionary electric motor. The concept features dual-rotor technology and is expected to enable super-efficient, powerful drives that offer plenty of range.

After a successful pilot project with promising results on the test rig, the BMW Group and DeepDrive are now planning their first field test. Various versions of the new drive will be installed into BMW Group models and their handling tested on different road conditions.

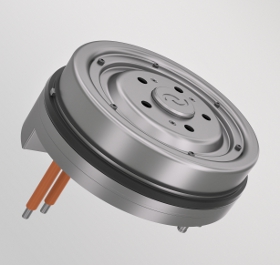

DeepDrive RM1500 integrated wheel hub motor unit. [Credit: Image courtesy of DeepDrive]

DeepDrive is a startup whose founders met while studying at TU Munich and participating in the technical university's student motorsport team. The company's innovative concept melds two electric motors into a single unit, creating an extremely compact drive that is energy efficient and has a high torque density.

In a conventional electric motor, the stator moves either an internal or an external rotor. With DeepDrive's dual-rotor concept, the stator drives both rotors simultaneously. The compact design and light weight of the unit allows for each wheel hub of an electric vehicle (EV) to have its own electric motor. The technology can also be used in a traditional, centralized drive system, where a central motor block powers the vehicle.

DeepDrive is currently developing three main in-wheel motor units for their line:

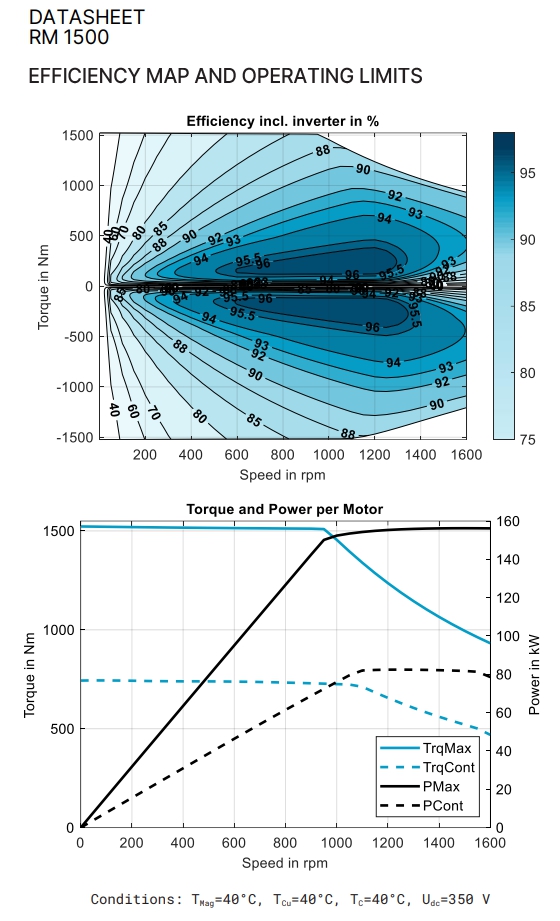

- RM1500 suitable for compact and mid-size EVs (peak power 150 kW/1,500 Nm peak torque/96.6% peak efficiency/weight 32 kg);

- RM1800 suitable for mid-size and large EVs (peak power 160 kW/1,800 Nm peak torque/97% peak efficiency/weight 35 kg); and

- RM2400 suitable for performance-focused EVs (peak power 250 kW/2,400 Nm peak torque/97% peak efficiency/weight 37 kg).

Key to the motor's operation is a revolutionary winding concept called distributed bar winding that uses 50% less magnet material, 80% less iron, and requires only simple manufacturing. Production-wise, a DeepDrive motor boasts less than 30% cost per Nm in comparison to the state-of-the-art EV motors available.

RM1500 motor unit data sheet. [Credit: Charts courtesy of DeepDrive]

For the overall DeepDrive system, the company says, "the integrated SiC MOSFET inverter, the automotive standard wheel hub unit, and the easy-to-use CAN interface make it plug & play for most electric mobility applications." An integrated drum brake is available. The units run on up to a 420-V battery supply, but 800-V versions are available. Lightweighting is also achieved because the DeepDrive units do not require a gearbox.

VIDEO: DeepDrive: Company technology breakthroughs.

VIDEO: DeepDrive: The In-Wheel Drive.

The RM1500 with integrated brake, a project realized with the help of automotive specialist Continental, was awarded "Innovation of the Year 2023" by Vehicle Dynamics International Magazine for the development of the Drive-Brake unit. The first stage of the collaboration was aimed at seeing a hydraulic brake integrated into the Drive-Brake unit. The second stage is planned to integrate the long-term dry braking system without hydraulic components into DeepDrive's innovative wheel hub drive.

According to the company, their overall motor technology boasts many technological benefits, including:

- Up to 20% efficiency increase;

- Plug-and-play with integrated inverter;

- Lowest noise emissions; and

- Lowest Total Cost of Ownership.

Alex Rosen, Deep Drive's co-founder and systems engineer, says in the company's technology video series: "Our dual-rotor, radial flux machine offers numerous advantages that set it apart from traditional electric motors. With minimal iron losses, it delivers exceptional partial load efficiency, achieving industry-leading torque density and power density while keeping material costs low.

"Our groundbreaking solution incorporates a dual-rotor, radial flux topology, integrating the benefits of an inner runner and an outer runner into a single electric machine. While the concept of a dual-rotor machine is not entirely new, our patented technology has overcome the manufacturing challenges associated with large-scale production, making it a significant breakthrough."

BMW was the first major manufacturer to get wind of DeepDrive and sign them up as technology partners. The carmaker has been intensifying collaborations with them since 2021. The startup's technology is already remarkably mature. "DeepDrive's prototype parts largely exceeded our specifications," says Karol Virsik, head of Research Vehicle Concepts and Technologies at the BMW Group. "That's really unusual at such an early stage and with a completely new technology."

"Our in-wheel motors deliver impressive performance figures, capable of generating up to 2,400 Nm of torque and 200 kW of power per wheel. This versatility enables their application across a wide range of electric vehicles, from small and compact models to large SUVs and luxury cars," says Rosen in the DeepDrive technology video series. Rosen adds that the issue of unsprung masses has been a topic of concern when it comes to in-wheel motors, but DeepDrive's lightweight units minimize unsprung masses. "The high power density of our machines allows us to reduce the size of the mechanical brake at the rear axle, or even eliminate it altogether. This ensures that the overall increase in unsprung masses when using our in-wheel motors remains negligible compared to traditional front axle-driven systems," he says.

After stints on test rigs, the proof of concept was deemed successful, delivering top results. The next step is to perform a real-world validation out on the road. The in-wheel motors will require less space and be more energy efficient, lighter, and less costly, making them an attractive option for a wide range of vehicle models -- and potentially highly scalable.

"It's alarming to realize that from plug to wheel, more than 40% of electric energy is wasted in the current state of EV technology," says Rosen. "While electric motors boast high efficiency of over 95% at high output power, the story changes when operating at lower power levels. Friction losses, iron losses, and splashing losses in the gearbox lead to a drastic reduction in efficiency during low-power operation."

"As a result, state-of-the-art drive systems struggle to maintain efficiency above 75% in everyday driving situations," says Rosen. DeepDrive believes their motor solutions can do better.

"DeepDrive has developed an exciting vision for the electric drive of the future," said Virsik. "The Startup Garage allows us to experiment with DeepDrive and work out what drives might look like in the generation after next."

You can read DeepDrive's whitepaper, "A Comprehensive Study on Different Motor Topologies Used in Passenger Car EV Segment," that has a lot more technology details, including on the special winding tech for their dual-rotor radial flux permanent magnet machine here.

Learn more at deepdrive.tech/technology.

Sources: BMW Group, BMW Startup Garage, DeepDrive

Published November 2024

Rate this article

View our terms of use and privacy policy