|

| November 19, 2024 | Volume 20 Issue 44 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Weird science: New anti-fatberg coating could help unclog city sewers

Engineers have invented a protective coating for concrete pipes that could help drastically reduce the formation of fatbergs in sewers.

By Will Wright, RMIT University

Fat, oil, and grease (known as FOG) -- notorious for solidifying inside pipes and concrete sewers -- cause half of all sewer blockages in the United States and 40% in Australia. The cost of these blockages in terms of maintenance and rehabilitation is estimated at $25 billion in the United States and $100 million in Australia per year.

It is the mixture of fat, oil, and grease with calcium and water in sewers that often leads to the formation of "fatbergs." A zinc-enhanced polyurethane coating developed by researchers at RMIT University in Australia offers a promising, sustainable solution by reducing the release of calcium from concrete blocks by up to 80% compared with uncoated concrete.

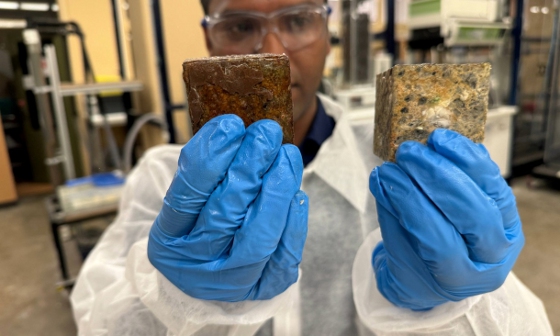

Dr. Biplob Pramanik shows the difference between a concrete block coated with his team's anti-fatberg invention (left) compared to a block without any coating (right) after undergoing an experiment that mimicked a sewer environment under extreme conditions to speed up the fatberg formation process. The white-colored blobs on the uncoated block are a mixture of fat, oil, and grease (FOG). [Credit: Will Wright, RMIT University]

The study, led by Dr. Biplob Pramanik, mimicked a sewer environment under extreme conditions that rapidly sped up the fatberg formation process over 30 days. It showed the coating reduced build-up of FOG on concrete by 30% compared to non-coated concrete.

"The reduction of fat, oil, and grease build-up can be attributed to the significantly reduced release of calcium from coated concrete, as well as less sticking of FOG on the coating surface compared to the rough, uncoated concrete surface," said Pramanik, director of Water: Effective Technologies and Tools (WETT) Research Center at RMIT.

"Traditional coatings like magnesium hydroxide, widely used for over two decades, are effective in controlling sewer corrosion but can inadvertently contribute to FOG build-up by interacting with fatty acids," he said.

The team's invention is stable in water and withstands temperatures up to 850 C. It is also self-healing at room temperature, meaning it can repair any damage to itself and extend its lifespan.

"We drew inspiration from the regenerative capabilities observed in nature, including human skin's ability to heal itself," Pramanik said.

Co-researcher Dr. Sachin Yadav said the team examined the healing performance of the coatings by inflicting surface scratches with a blade.

"The creation of surface scratches on the self-healing polyurethane coating sample triggered the healing process," Yadav said. "After the healing period, we observed a noticeable improvement in the surface scratches."

Next steps

The team is developing an improved coating to achieve a greater reduction of FOG deposition in sewers by enhancing its self-healing capabilities and mechanical strength.

Pramanik is also the chief investigator for a recently announced ARC Linkage Project that will develop an advanced grease interceptor for restaurants and other food service establishments to remove small FOG particles more effectively than current technologies.

See "Novel hybrid coating material with triple distinct healing bond for fat oil and grease deposition control in the sewer system" published in the Chemical Engineering Journal.

Published November 2024

Rate this article

View our terms of use and privacy policy