|

| February 04, 2025 | Volume 21 Issue 05 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

6 new NASA materials experiments on the space station worth knowing about

NASA regularly conducts ground-breaking research in space on materials like metals, foams, and crystals. The latest research on the space station could lead to next-generation technology that both enables deep-space exploration and benefits humanity. Here are six new projects that we think are worth knowing about.

1. Advancing construction and repairing techniques with liquid metals

Researchers are looking at the effects of microgravity on the liquid metals formed during brazing, a technology used to bond materials at temperatures above 450 degrees Celsius. The Brazing of Aluminum alloys In Space (BRAINS) experiment aboard the International Space Station studies how alloys join with a range of other materials, such as ceramics or other metals.

ROSCOSMOS cosmonaut Oleg Novitskiy swaps hardware inside the U.S. Destiny laboratory module's Microgravity Science Glovebox (MSG) for a physics investigation. The study known as Solidification Using a Baffle in Sealed Ampoules, or SUBSA, explores improving technology used in producing semiconductor crystals. [Credit: Image courtesy of NASA]

Brazing is a technology of bonding similar (e.g,. an aluminum alloy to aluminum) or dissimilar (e.g., aluminum alloy to ceramics) materials at temperatures above 450°C, facilitated by an inclusion of a molten braze interlayer. Moreover, brazing may be executed as a repair technique by filling clearances/cracks with a liquid braze.

Bonding takes place upon liquid phase solidification and subsequent formation of the metallurgical bond at the interface of the joint/repair domain. Hence, a solid state and a capillary flow liquid state of mating surfaces and molten interlayer metal, respectively, have dominant roles in executing the physical phenomena involved in an efficient manner. In space, brazing could be used to construct vehicles, habitats, and other systems needed for space missions, and repair them if damaged. Advanced brazing technologies discovered in space may also be used in the construction and repair of structures on Earth.

2. Researching ways to make stronger metal

Metal alloys, which are created by combining two or more metallic elements, are used in everything from hardware to kitchen appliances, automobiles, and even the space station itself. Alloys are created by cooling a liquid metal until it hardens into a solid.

Researchers on the space station are investigating how metal alloys melt and take shape in a controlled microgravity environment. While brazing aims to repair or bond two separate materials, this experiment looks at casting or molding things from liquid metals. In metal castings, the solid grows by forming millions of snowflake-like crystals called dendrites. The shape of the dendrites affects the strength of the metal alloys.

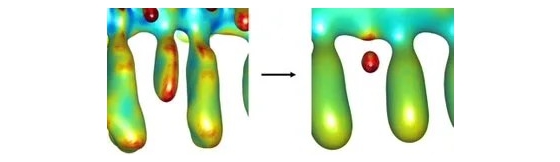

This preflight image of the Dendrite Fragmentation and Morphology during Melting and Solidification (DFM) investigation shows a small portion of an experimentally determined dendrite (left). The same portion (right) shows the formation of a fragment and other morphological changes after a simulated temperature change. Colors show the mean curvature of the dendrite interfaces (red corresponds to high positive curvature, blue to high negative curvature, and green to zero curvature). [Credit: Image courtesy of P. Voorhees, Northwestern University/NASA]

Findings are expected to significantly impact our ability to produce metals with greater strength, for both space and Earth applications.

3. Improving materials used for high-powered lasers

Another study on the space station is looking at the growth of semiconductor crystals based on Zinc selenide (ZnSe) in microgravity. ZnSe is an important semiconductor used on Earth for optical devices and infrared lasers.

Researchers are investigating the impact of microgravity on the growth of these crystals and comparing the results to those grown on Earth. A better understanding of the impact of microgravity on crystal growth could open the door to expanded commercial use of space.

The main scientific objective is to study the effects of gravity-driven fluid flows on the structural, electrical, and optical characteristics of the grown crystals by comparing the crystals grown on Earth and in space. The samples are processed in the Low Gradient Furnace (LGF) installed in the Materials Science Laboratory (MSL) inside of the Materials Science Research Rack (MSRR) on the International Space Station

Quality ZnSe-based crystals are integral to special optical applications, including optical windows, infrared (IR) lasers, and optical wavelength conversion devices.

4. Improving performance and lowering cost of "superglass"

Scientists are conducting experiments on supercooled metal oxides (space soil and rock) to better understand how molten materials can be processed in microgravity. Manufacturing new products in space is critical to long-term efforts to develop habitats in space and on other planets. It will require the use of available resources in space, including soil and rocks.

The Microgravity Investigation of Thermophysical Properties of Supercooled Molten Metal Oxides uses prototypical metal oxide systems based on aluminate, silicate, and titanate binaries to develop the basis for understanding the interplay between thermophysical properties, atomic structure, and the properties of products made both in microgravity and on Earth.

Molten metal oxides are also key to Earth-based functional glass products for a wide variety of applications. Data from the research could help improve the performance and lower the cost of materials that are used in the production of cell phone displays, lasers, and glass for automobiles.

5. Exploring stability and mechanics of foams and bubbly liquids

Studying how foams and bubbly liquids evolve in microgravity over time is another important NASA investigation. Even though foams can support shear stress statically like an elastic solid, over time the gas and liquid phases separate, and understanding the degree of stability is crucial to control applications that will allow humans to thrive in deep space.

These experiments aim to provide guidance for how to control the flow and separation of bubbly liquids. This knowledge is crucial for developing a water recovery and recycling device for future space exploration to Mars. In a closed-loop processing system of water aboard future Mars-bound spacecraft, recovered water will be contaminated with both gas bubbles and surface-active chemicals. Therefore, robust foams and bubbly liquids would be created. These foams and bubbly liquids must be pumped around, and the gas must be separated from the liquid.

Foams are useful for fire suppression too.

On Earth, foams are found in everything from food and cosmetics to paper and petroleum. A better understanding of their stability and mechanics is important for creating sustainable, more efficient processes, and improved materials.

6. Advancing 3D printing and manufacturing through "soft matter" research

Space exploration to Mars and beyond will require astronauts to have the ability to build new equipment and materials in space. To make that a reality, space station researchers conducted a number of experiments looking at the behavior of colloids, or "soft matter," in a microgravity environment.

NASA astronaut Jeanette Epps prints samples of stainless steel to demonstrate microgravity operation of the Metal 3D Printer from ESA (European Space Agency). Crew members could use this technology to manufacture tools and parts on demand, reducing the need to bring along spare parts on missions to the Moon and Mars. Lessons learned also could improve metal additive manufacturing processes on Earth. [Credit: NASA]

Assembling structures in microgravity provides insight into the relation between particle shape, crystal symmetry, density, and other fundamental factors. In these experiments, the constituent particles are colloidal spheres and ellipsoids -- or small particles suspended within a fluid medium. The research goal is to produce various colloidal structures and study the dynamics of crystal nucleation and growth.

Future long-duration space voyages need the capability to use self-replication and self-assembly to make materials and devices that can be repaired or replaced in space. 3D printing and additive manufacturing meet both of these needs. This research could have a variety of applications on Earth, including the development of chemical energy, improvements to communications technologies, and enhancements to photonic materials used to control and manipulate light.

Source: NASA

Published February 2025

Rate this article

View our terms of use and privacy policy