|

| March 11, 2025 | Volume 21 Issue 10 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New super sapphire resists scratches, glare, fog, dust

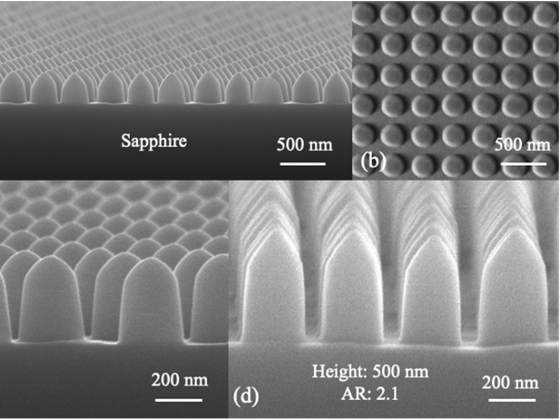

A sample of the new sapphire-based nanostructures created in the lab of Professor Chih-Hao Chang at UT Austin. [Credit: Image courtesy of The University of Texas at Austin]

A phone screen you can't scratch no matter how many times you drop it. Glasses that prevent glare. A windshield that doesn't get dusty. These are all possibilities thanks to a new way to produce sapphire.

Researchers at The University of Texas at Austin have discovered techniques to bestow superpowers upon sapphire, a material that most of us think of as just a pretty jewel. However, sapphire is seen as a critical material across many different areas, from defense to consumer electronics to next-generation windows, because it's nearly impossible to scratch.

"Sapphire is such a high-value material because of its hardness and many other favorable properties," said Chih-Hao Chang, associate professor in the Walker Department of Mechanical Engineering and leader of the new research. "But the same properties that make it attractive also make it difficult to manufacture at small scales."

Professor Chih-Hao Chang (left) with Mehmet Kepenekci (right) and Andrew Tunell (center), members of his lab. [Credit: Image courtesy of The University of Texas at Austin]

Chang and his team hope to ease this challenge with new sapphire-based nanostructures as documented in Materials Horizons. The nanostructures show the highest aspect ratio yet for this material, which enables its superpowers without completely losing its stiffness and hardness.

The research

While not quite as scratch resistant as traditional bulk sapphire -- the nanostructures are comparable to tungsten or traditional glass in that way -- these new sapphire nanostructures repel fog, dust, and glare with self-cleaning capabilities.

"This is very exciting, since nanostructures are traditionally seen as being fragile, but making them in sapphire can solve this problem," said Kun-Chieh Chien, a recent Ph.D. graduate from Chang's lab and one of the lead authors of the paper.

Inspired by a moth eye, the tapered profile of the sapphire nanostructures enhances light transmission and reduces glare. The nanostructures' high surface energy and aspect ratio create a superhydrophilic surface to prevent fog. The structures can also be treated to be a superhydrophobic surface to allow water droplets to roll off the surface, mimicking the lotus leaf effect.

Scanning electron microscopy views of the new sapphire-based nanostructures. [Credit: Image courtesy of The University of Texas at Austin]

"Our sapphire nanostructures are not only multifunctional but also mechanically robust, making them ideal for applications where durability and performance are critical," said Mehmet Kepenekci, a graduate student in Chang's lab and one of the paper's lead authors.

According to the Materials Horizons paper, "The nanostructures were patterned using interference lithography, and then transferred to a sapphire substrate using reactive ion etching." The process is specialized, because "Sapphire has a low etching rate due to its chemical stability." For this study, the researchers say their sapphire nanostructures "were patterned over an area of 30 mm by 30 mm for demonstration of their material properties, but the developed process is scalable for larger areas."

Chang said for now, a final product using this technology would have the nanostructures etched into a sapphire substrate. "We also have some on-going work that aims to create a coating of the sapphire nanostructures, which can then be applied to other surfaces," he said.

Why it matters

This technology has a wide variety of benefits. For consumers, it could lead to smartphones that are easier to read in challenging lighting conditions, lenses and windows that don't fog up, cameras that aren't prone to glare, and hardy windshields that don't get dusty.

As we embark on the next generation of space travel, the anti-dust properties could ensure mission-critical equipment doesn't get caked in dust during landing missions on other planets, for example. It could lead to the creation of stronger infrared sensors and protective windows in defense applications.

"Our self-cleaning sapphire surfaces can maintain 98.7% dust-free area using gravity alone," said Andrew Tunell, the student who conducted the dust adhesion experiments. "This is a significant improvement over existing dust-mitigation technologies and is particularly beneficial for applications in space, where water is not readily available for cleaning."

What's next

The researchers aim to bring this technology to life, and they're looking to improve it in several ways. They're scaling up fabrication to apply these nanostructures over larger samples, improving mechanical and chemical properties to enhance its abilities and exploring even more real-world applications.

Source: The University of Texas at Austin

Published March 2025

Rate this article

View our terms of use and privacy policy