|

| March 11, 2025 | Volume 21 Issue 10 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

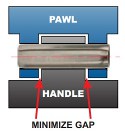

Superior fastening solution for securing rotating components to a shaft

Shaftloc® fasteners offer distinct advantages over other fastening methods when securing rotating components to a shaft. The key to this compact, efficient design is its asymmetric thread geometry that produces a greater clamping force -- outperforming other fastening methods. Shaftloc is a patented fastening system manufactured by SDP/SI.

Shaftloc® fasteners offer distinct advantages over other fastening methods when securing rotating components to a shaft. The key to this compact, efficient design is its asymmetric thread geometry that produces a greater clamping force -- outperforming other fastening methods. Shaftloc is a patented fastening system manufactured by SDP/SI.

Learn more.

Print 316L stainless steel on Markforged printers

316L Stainless Steel is now available for use with Markforged FX10 printers, allowing users to manufacture high-strength, accurate parts for demanding applications such as food and beverage processing, automotive, chemical and petrochemical processing, medical devices, and marine environments. This filament is safe and easy to handle. It makes machinable and polishable parts that have excellent corrosion resistance.

316L Stainless Steel is now available for use with Markforged FX10 printers, allowing users to manufacture high-strength, accurate parts for demanding applications such as food and beverage processing, automotive, chemical and petrochemical processing, medical devices, and marine environments. This filament is safe and easy to handle. It makes machinable and polishable parts that have excellent corrosion resistance.

Learn more.

10 best updates from the last 5 years: SOLIDWORKS

Follow along with the experts at TriMech Group as they chronicle the top feature updates in SOLIDWORKS. Are you still using SOLIDWORKS 2020 -- or an even older version? Find out what you are missing, such as: enhanced rendering and new technical drawing tools; improved file sharing, collaboration, and workflows; advanced customization and UI improvements; faster and more efficient assemblies and simulations; and more.

Follow along with the experts at TriMech Group as they chronicle the top feature updates in SOLIDWORKS. Are you still using SOLIDWORKS 2020 -- or an even older version? Find out what you are missing, such as: enhanced rendering and new technical drawing tools; improved file sharing, collaboration, and workflows; advanced customization and UI improvements; faster and more efficient assemblies and simulations; and more.

View the TriMech video.

Engineer's Toolbox: How to design the optimum hinge

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Read the full article.

Innovative new robo welding gun

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Learn more.

What's a SLIC Pin®? Pin and cotter all in one!

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

Learn more.

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

Full-color 3D-printing Design Guide from Xometry

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

Get the Xometry guide.

Tech Tip: How to create high-quality STL files for 3D prints

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Read this detailed and informative Markforged blog.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

Engineer's Toolbox: How to pin a shaft and hub assembly properly

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

Read this very informative SPIROL article.

What's new in Creo Parametric 11.0?

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Read the full article.

What's so special about wave springs?

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

View the video.

Simple method discovered to break down plexiglass for recycling

Polymer chemists at research university ETH Zurich in Switzerland have discovered a surprising way to fully break down PMMA plastic -- commonly known as acrylic glass or plexiglass -- into its monomer building blocks. The process remains unaffected by the presence of additives.

By Daniel Meierhans for ETH Zurich

Today, plastics recycling is primarily limited to the collection of sorted PET or polyethylene beverage bottles. The plastic collected is of identical chemical composition, with polymer molecules of similar lengths. The additives used to enhance properties such as color, softness, or sunlight resistance are also similar.

This process enables plastic to be melted down and reformed into new bottles. In contrast, plastics of various types and qualities (known as mixed plastics) are usually incinerated (to generate heat in cement plants, for example).

A team of scientists led by Athina Anastasaki from the Laboratory of Polymeric Materials at ETH Zurich has discovered a method that enables the near-complete breakdown of acrylic glass into its monomer building blocks. By using additives, these building blocks can be easily purified through distillation into virgin-grade starting products for the synthesis of new plexiglass polymers.

The potential implications are significant: With a global annual production of around 3.9 million tons, acrylic glass (chemically known as PMMA or polymethyl methacrylate) is a durable and lightweight material. It is gaining in popularity in the aerospace and automotive industries, in the manufacture of screens and monitors, and in the construction industry.

The process developed by the ETH researchers and presented in the journal Science is highly robust. It is also effective with very long polymer chains made up of 10,000 monomer building blocks. Additionally, the presence of additives such as copolymers, plasticizers, dyes, and most other plastics has minimal impact on chain scission. Even when using multicolored acrylic glass from the DIY market, the yield remains between 94 and 98%.

Surprisingly simple process

"Our process is extremely simple," says Anastasaki. "All we need is a chlorine-based solvent and to heat the dissolved recycling mixture to a temperature between 90 and 150 degrees Celsius to start the depolymerization reaction with the aid of UV or visible light."

The ETH professor was amazed at how straightforward the process is. Like many other important plastics, such as polyethylene or polypropylene, acrylic glass polymers consist of a polymer chain of carbon atoms with various side groups branching off, depending on the type of plastic. Until today, these uniform carbon chains have posed an insurmountable chemical challenge for targeted splitting into monomers, as they do not provide specific points of attack for splitting reactions.

The only method currently used in industry that completely breaks down homogeneous carbon chains is pyrolysis. This involves the thermal decomposition of carbon chains at around 400 C. However, these reactions are non-specific, resulting in a mixture of various cleavage products. The large amount of energy required for this process, along with the costs associated with purifying the resulting mixture, severely limits the economic efficiency of pyrolysis.

For several years, various research groups have been experimenting with modified polymers. They have introduced easily detachable molecular groups at the ends of the polymer chains, which then trigger deconstruction from the end of the chain. In this way, the researchers have achieved yields up to 90%.

However, these designer polymers have various major disadvantages. In addition to the need to be first integrated into established plastic production, their reactive end groups significantly limit the thermal stability of the polymers -- and thus their possible uses. Furthermore, many of the commonly used plastic additives reduce the yield of the reactions, with the result that depolymerization only works to a limited extent, even in the case of the long polymer chains that often occur in commercial plastics.

The solvent determines the reaction

As is so often the case in chemistry, the new method was discovered by chance. As Anastasaki explains, "We were actually looking for specific catalysts that would promote the targeted breakdown into monomers. But a control experiment led to the surprising revelation that the catalyst was not even necessary." The chlorinated solvent in which the crushed acrylic glass sample was dissolved was enough to virtually completely split the polymer with the help of UV light.

When the researchers had a closer look at the splitting reaction, they came across a surprising mechanism. They discovered that the chemically active particle in the reaction was a chlorine radical that is split off from the chlorinated solvent when excited by UV light. What was unexpected was that the high-wavelength light can break the chlorine's bond with the solvent molecule. This happens as part of a relatively esoteric photochemical phenomenon, whereby a very small fraction of the solvent molecules absorbs high-wavelength UV light.

Anastasaki was able to count on the help of specialists from other ETH research groups to investigate the mechanism behind the splitting reaction. Tae-Lim Choi from the Laboratory of Polymer Chemistry calculated the theoretical electronic states of the molecules involved, while Gunnar Jeschke from the Institute of Molecular Physical Science carried out electron paramagnetic resonance measurements, which were used to experimentally verify the theoretical predictions.

The chlorine must go

In the future, however, Anastasaki wants to dispense with the chlorinated solvent in her recycling process. "Chlorinated chemical compounds harm the environment. Our next goal is, therefore, to modify the reactions to enable them to work without the chlorinated solvent," she says.

It is still unclear how and when the ETH method will be implemented in practice. In any case, Anastasaki and her team of researchers have opened the door to new recycling methods that can be used to bring about the targeted breakdown of previously chemically inaccessible carbon chains of plastics.

Published March 2025

Rate this article

View our terms of use and privacy policy