|

| April 08, 2025 | Volume 21 Issue 14 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Supersonic speed limit for strong metal bonding pinpointed

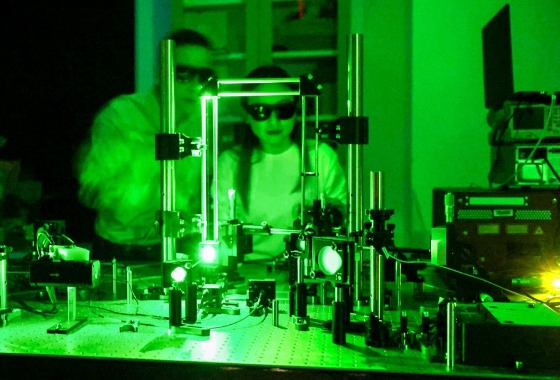

Assistant professor Mostafa Hassani (left) and doctoral student Qi Tang work with a custom-built laser optic platform to launch supersonic microprojectiles and study how high-speed metallic collisions form solid-state bonds. [Credit: Photo courtesy of Cornell Engineering]

By Syl Kacapyr, Cornell Engineering

Faster isn't always better when it comes to high-speed materials science, according to new Cornell research showing that tiny metal particles bond best at a precise supersonic speed.

In industrial processes like cold spray coating and additive manufacturing, tiny metal particles travel at extreme speeds and slam into a surface with such force that they fuse together, forming strong metallic bonds. This rapid, high-energy collision builds up layers of material, creating durable, high-performance components. Understanding how and why these bonds form, and sometimes fail, can help optimize manufacturing techniques and lead to stronger materials.

In a study published March 31 in the Proceedings of the National Academy of Sciences, Cornell scientists launched aluminum particles, each about 20 micrometers in diameter, onto an aluminum surface at speeds up to 1,337 meters per second (m/sec) -- well beyond the speed of sound -- and used high-speed cameras to record the impacts.

The results showed that bond strength increased steadily as impact velocity rose, but as velocity increased beyond 1,060 m/sec, the bond strength began to decline. By 1,337 m/sec, the particles barely adhered to the surface at all.

"It was a total surprise," said senior author Mostafa Hassani, assistant professor in the Sibley School of Mechanical and Aerospace Engineering and in the Department of Materials Science and Engineering, both in Cornell Engineering.

"The expectation was that as you go higher, you should get better bonding quality," Hassani said. "This study shows that, in fact, there is a peak in bond strength and higher speed doesn't necessarily lead to higher strengths."

A microprojectile launch pad in the Hassani Group laboratory can shoot metal particles at supersonic speeds and capture the impact using high-speed cameras. [Credit: Photo by Charissa King-O'Brien/Cornell Engineering]

The researchers attribute this decline in bond strength to a phenomenon called "intensified elastic recovery." At extremely high velocities, the surface material loses some of its ability to absorb energy through deformation and, instead, more energy is stored as elastic strain, causing the particles to snap back after impact. This rebound effect stretches and damages the interface, weakening the bond.

In some industrial processes, extremely high velocities can erode or even melt the surface, preventing proper bonding. Qi Tang, doctoral student and lead author of the study, said the new findings can help optimize manufacturing processes by providing insight into why erosion occurs.

"Previously, people in industry may have speculated that erosion is caused by fast-moving particles plowing through the substrate surface or by melting at the interface," Tang said. "But now we see that when you give a super high velocity to a particle, the increased rebounding tendency can cause a previously bonded particle to detach, preventing material buildup."

While the study focused on aluminum, the researchers said the mechanism responsible for peak bonding velocity is likely universal across all metals and alloys. Subsequent studies will investigate how particle size influences the results and explore potential ways to engineer both the particles and the substrate surface to maximize bonding strength.

The research was supported by the National Science Foundation, the Japan Science and Technology Agency, and the Japan Society for the Promotion of Science.

Published April 2025

Rate this article

View our terms of use and privacy policy