|

| April 22, 2025 | Volume 21 Issue 16 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

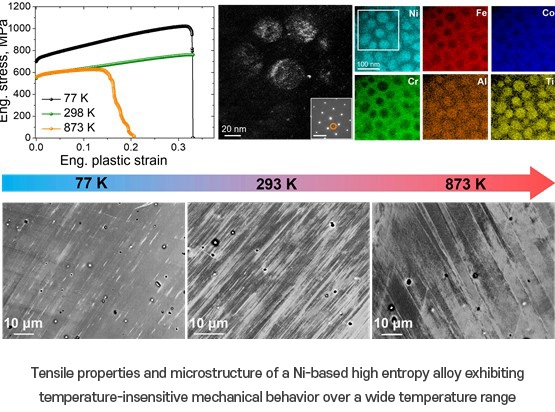

Nickel super alloy withstands huge temp range

Researchers in South Korea have developed a new alloy that maintains its strength and ductility across extreme temperatures ranging from -196 to 600 C -- a material that should be of significant interest to the aerospace and automotive industries.

Most metals used in everyday life are sensitive to temperature changes. Consequently, conventional metal materials are typically optimized for performance within a narrow temperature range, limiting their effectiveness in environments with dramatic temperature fluctuations.

To overcome this challenge, a research team at POSTECH (Pohang University of Science and Technology), led by Professor Hyoung Seop Kim from the Department of Materials Science and Engineering, Graduate Institute of Ferrous Technology, and Department of Mechanical Engineering, introduced the concept of the "Hyperadaptor" and developed a nickel-based high-entropy alloy (HEA) that embodies this idea.

The newly developed HEA demonstrates nearly constant mechanical performance across a wide temperature range -- from cryogenic conditions at -196 C (77 K) to high heat at 600 C (873 K). This remarkable stability is attributed to the presence of nanoscale L1 precipitates*, which are uniformly distributed within the alloy. These fine particles act as reinforcements that inhibit deformation, while the alloy's internal structure accommodates stress through consistent slip behavior, regardless of temperature.

[Image courtesy of POSTECH]

The Ni-HEA material, Ni35(FeCoCr)53Al7Ti5, is made of aluminum, titanium, chromium, iron, cobalt, and nickel.

This development holds significant promise for applications that involve sudden or extreme temperature changes, such as rocket or jet engines, automotive exhaust systems, power plant turbines, and pipelines. The alloy's ability to maintain stable performance under such conditions can greatly enhance both safety and efficiency in these demanding environments.

"Our HEA breaks through the limitations of existing alloys and establishes a new class of temperature-insensitive materials," said Professor Kim. "The Hyperadaptor concept represents a breakthrough in developing next-generation materials with consistent mechanical behavior even under extreme conditions."

The study was supported by the South Korean Ministry of Science and ICT through the Nano and Materials Technology Development Program and by Hyundai Motor Group.

* A type of precipitate formed in FCC-based alloys, characterized by an ordered atomic arrangement. Representative examples include Ni3Al and Ni3Ti. These precipitates hinder dislocation motion, thereby enhancing the strength and ductility of the material.

Source: Pohang University of Science and Technology

Published April 2025

Rate this article

View our terms of use and privacy policy