|

| January 20, 2015 | Volume 11 Issue 03 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

CIDEAS uses 3D scanning and printing to retrofit Lotus 340R, 'purest driving machine on the planet'

By Bob Cramblitt

This CIDEAS retrofitted Lotus 340R begs the question: "Is it an OEM part or a 3D-printed replacement?"

Mike Littrell is a rare combination of visionary and realist.

While others tilt at windmills by promising an entire car made of 3D-printed parts, Littrell's company, CIDEAS, is pursuing a more practical, but still bold, agenda: using 3D scanning and printing technologies to create and manufacture replacement parts for rare vehicles.

CIDEAS proved at the RAPID show, held in Detroit in June 2014, that the company could use scanning, software, and printing products from 3D Systems to help produce more than 40 replacement components for a Lotus 340R, a legendary concept car of which only 340 were made in 1998.

The CIDEAS booth at RAPID 2014 in June. Visitors to the booth had an "aha" moment when seeing a Lotus 340R retrofitted with 3D-scanned and -printed parts.

Thinking big

Littrell, a self-confessed car guy, got the inspiration for the Lotus project while driving to the 3D Print show in New York City in February 2014. Thinking about the upcoming RAPID show, he wanted to do something big, but real, for the Detroit audience.

"A lot was being written about projects to build an entire 3D-printed car," says Littrell. "But 3D printing an entire car is not a viable solution at this time and is not likely to be for decades. I think the market for replacement components and custom-made items for rare vehicles is an immediate opportunity."

Although automotive parts is a small part of CIDEAS' current business, the company has forged a reputation for innovation in that market. At the Additive Manufacturing User Group (AMUG) conference in Tucson in early 2014, the company's 3D-printed scale model of a 1921 Miller 91 car finished first in advanced finishing and third in the advanced concept categories in the technical excellence competition.

Mike Littrell, president of CIDEAS, next to a 3D Systems iPro 8000 stereolithography printer used for the Lotus 340R project.

Marrying two loves

In his quest to make a big splash at RAPID, Littrell started to search dealerships in the Midwest U.S. to find a Lotus 340R, called by Road & Track magazine "simply the purest driving machine on the planet."

Whether by fate or coincidence, he found the exact model he was searching for at one of the first dealers he contacted in Michigan, not too far from CIDEAS' headquarters in Crystal Lake, IL. A little eerie, considering that only 11 Lotus 340Rs are thought to have been imported to the United States.

The car was in excellent condition, with 190 original miles on it. What kind of person takes a dream car and systematically replaces perfectly good parts?

"I wanted to marry my two greatest loves: 3D printing and cars," says Littrell. "It would be a validation of our ability to replace very rare car parts with 3D-printed parts that not only match, but in most cases, exceed the aesthetics, performance, and durability of the originals."

After obtaining the car, an immediate challenge lay ahead: Finding the 3D scanning hardware and software to capture and process the complex curves and intricate design points of the car. Oh, and one small hurdle: Despite its computer-aided design (CAD) and 3D printing expertise forged over 25 years, CIDEAS had little knowledge and no tools for 3D scanning of parts and assemblies.

Fast-track 3D scanning

Littrell wanted a 3D scanner and processing software in one integrated package. He found it in Geomagic Capture from 3D Systems. Geomagic Capture brings together in one package a compact, ultra-precise, blue-light LED scanner and software that enables designers to quickly build a 3D model from multiple scans and import it directly into specific CAD applications.

Dan Williams, whom Littrell calls the company's "self-taught software guru," was the natural choice to take on scanning and modeling duties, since he was the resident SolidWorks CAD/CAM user. But Williams had no 3D scanning experience.

"I'd never scanned anything," says Williams. "My scanning knowledge was slim to none."

When the Geomagic Capture system arrived, Williams went to work immediately, having only four weeks to create more than three-dozen parts. The first scans he did were of the Lotus' front hood panel, requiring about 15 to 20 scans to capture.

After his initial scanning, he participated in a one-hour webinar session from 3D Systems, using his own hood data for the tutorial.

"I did the webinar in the afternoon and immediately began modeling," says Williams. "I went home that night and came in the next morning and continued working. By about 10 a.m., I had a complete surface model in Geomagic Capture and was using the 3D Systems interface to export it directly into SolidWorks, where I put in the mechanical features. The process was smooth and fast."

From there, it was a matter of repeat as necessary, at various degrees of complexity.

Perfect fit, first time

The finished assemblies created by CIDEAS for RAPID include the front hood, rear deck-lid, fenders, and rear wing of the car. The deck-lid was modified after surface capture to include a cold air intake and vents. The wing was expanded to create greater drag at higher speeds. Original fiberglass parts, such as the front hood, were replaced with ABS parts that provide greater flexibility and resistance to cracking.

A breakout of the Lotus 340R parts remodeled and replaced for the RAPID show in Detroit.

"We captured and created a fully functional air intake system and the rest of the parts, all strengthened and made lighter, within four weeks," says Littrell.

Scans for the trunk were exported to PTC Creo software and sent out to Design Department Inc. in Pleasant Prairie, WI, for additional design work.

Final models were printed in the materials best suited to meet design, performance, and maintenance needs. 3D Systems iPro 8000 systems were used for all the SLA (stereolithography) parts and the 3D Systems sPro60 HD/HS for the SLS (selective laser sintering) parts.

"We had 170 hours of built parts, and they all fit on the first try," says Littrell.

Finally, the fenders

The fenders presented one of the greatest challenges and still had not been scanned two weeks before RAPID in Detroit. Like everything in the Lotus 340R, they are far from stock -- they're free-floating above the wheels, protruding outside the body of the car in a motorcycle-style design, with tight-fitting cutaways to accommodate brake lines, springs, and other components.

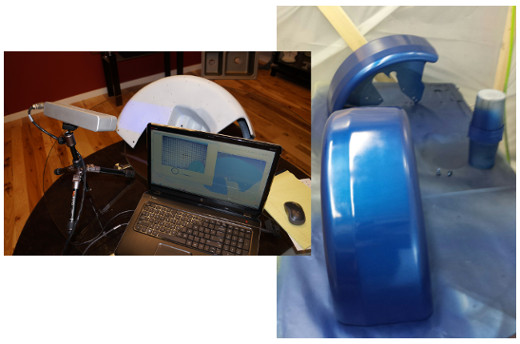

Geomagic Capture, a 3D scanner with integrated processing software, enabled CIDEAS to quickly capture part geometry to accelerate modeling and 3D printing. CIDEAS used 3D scanning and printing to recreate the one-of-a-kind fenders for the Lotus 340R in three or four days to make the deadline for delivering the car to the RAPID show.

The dark-colored fenders were spray-painted in a white rubber latex to facilitate scanning, after which the rubber was peeled off. Within three or four days, the fenders were recreated, 3D printed in ABS material, and mounted for the show.

A close-up of the finished rear of the car, with multiple replacement parts scanned, modeled, 3D-printed, finished and assembled.

The "aha" moment

The reaction to the retro-fitted Lotus at RAPID was just what Littrell wanted.

"People were blown away," he says. "I think it created that 'aha' moment where everyone understood the implications of 3D scanning and printing in the rare automotive parts aftermarket."

"With the Lotus 340R project, CIDEAS demonstrates the great potential of 3D printing for rare or highly personalized replacement parts," says Mark Abshire, a 3D-printing consultant and advisor to the AMUG Board of Directors.

Close-up of the rear of the retrofitted Lotus 340R, with new rear deck-lid, fenders, wing, and cold air intake and vents.

Ramping up development speed

While showcasing the Lotus 340R at RAPID was an initial goal for CIDEAS, it was hardly an endpoint.

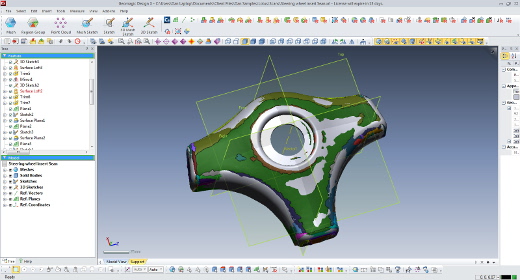

Shortly after the show, work continued on the Lotus 340R, including scanning, modeling, and 3D printing a washer-fluid reservoir and a custom steering-wheel insert. This time, Geomagic Design X software, known for its ability to produce history-based 3D CAD models directly from scans, was incorporated into the process.

Once again, Williams dove into the work after only an hour of training and started creating accurate models immediately.

"Geomagic Design X allows us to extract splines directly from the scan data," says Williams. "We were able to create a mesh model for the reservoir with an exact design tree for SolidWorks within a couple of hours. It saved us at least an hour or two of modeling work. It's very powerful to be able to generate feature-based, editable solid models from 3D scans for direct import into SolidWorks, PTC Creo, and other CAD packages."

After the RAPID show, CIDEAS used Geomagic Design X software to generate manufacturing-ready CAD models directly from scan data.

Both the washer-fluid reservoir and the steering wheel insert were printed on a 3D Systems Projet sPro 60 using the lighter, more durable Duraform GF material. The fenders, initially printed in ABS, were also reprinted in Duraform GF.

Side-view mirror mounts fresh from printing on a 3D Systems sPro60 HD/HS SLS system.

Beyond four wheels

Even while working on the Lotus project, Dan Williams was already leveraging his newly acquired 3D scanning and modeling skills for CIDEAS clients in the medical field and other industries. As for Mike Littrell, he's literally brought his work home after purchasing a 3D printer for his 11-year-old daughter.

"I have to laugh," says Littrell. "I have one of the largest 3D printing service bureaus in the world, and I spent five hours creating a one-inch frog for my daughter. But she was soon able to make starfishes for all her friends. Kids her age and younger will never know a world without 3D printing."

Bob Cramblitt is a freelance writer specializing in technologies that transform the way we live, work, and create.

Published January 2015

Rate this article

View our terms of use and privacy policy