|

| April 18, 2017 | Volume 13 Issue 15 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox: How to design the optimum hinge

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Read the full article.

Innovative new robo welding gun

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Learn more.

What's a SLIC Pin®? Pin and cotter all in one!

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

Learn more.

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

Full-color 3D-printing Design Guide from Xometry

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

Get the Xometry guide.

Tech Tip: How to create high-quality STL files for 3D prints

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Read this detailed and informative Markforged blog.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

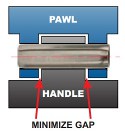

Engineer's Toolbox: How to pin a shaft and hub assembly properly

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

Read this very informative SPIROL article.

What's new in Creo Parametric 11.0?

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Read the full article.

What's so special about wave springs?

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

View the video.

New Standard Parts Handbook from JW Winco

JW Winco's printed Standard Parts Handbook is a comprehensive 2,184-page reference that supports designers and engineers with the largest selection of standard parts categorized into three main groups: operating, clamping, and machine parts. More than 75,000 standard parts can be found in this valuable resource, including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components.

JW Winco's printed Standard Parts Handbook is a comprehensive 2,184-page reference that supports designers and engineers with the largest selection of standard parts categorized into three main groups: operating, clamping, and machine parts. More than 75,000 standard parts can be found in this valuable resource, including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components.

Get your Standard Parts Handbook today.

Looking to save space in your designs?

Watch Smalley's quick explainer video to see how engineer Frank improved his product designs by switching from traditional coil springs to compact, efficient wave springs. Tasked with making his products smaller while keeping costs down, Frank found wave springs were the perfect solution.

Watch Smalley's quick explainer video to see how engineer Frank improved his product designs by switching from traditional coil springs to compact, efficient wave springs. Tasked with making his products smaller while keeping costs down, Frank found wave springs were the perfect solution.

View the video.

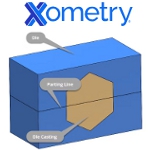

Top die casting design tips

You can improve the design and cost of your die cast parts with these top tips from Xometry's Joel Schadegg. Topics include: Fillets and Radii, Wall Thicknesses, Ribs and Metal Savers, Holes and Windows, Parting Lines, and more. Follow these recommendations so you have the highest chance of success with your project.

You can improve the design and cost of your die cast parts with these top tips from Xometry's Joel Schadegg. Topics include: Fillets and Radii, Wall Thicknesses, Ribs and Metal Savers, Holes and Windows, Parting Lines, and more. Follow these recommendations so you have the highest chance of success with your project.

Read the full Xometry article.

'The day the drones stopped': U.S. Army tests counter UAV systems at Fort Sill

Pvt. Shamar Paulhill (left) and Pfc. Sergio Torres, both air missile defense crewmembers from 108th Air Defense Artillery from Fort Bragg, use an anti-unmanned aerial vehicle defense system (AUDS) to search the skies of Fort Sill for UAVs on April 6 during the Maneuver Fires Integrated Experiment (MFIX). [Photo Credit: Monica K. Guthrie]

By Monica K. Guthrie

On a hill in southwest Oklahoma, Soldiers and civilians have been testing equipment that can assist service members in the fight against unmanned aerial vehicles (UAVs). The testing took place during Fort Sill's Maneuver Fires Integrated Experiment (MFIX) from April 3-14.

The equipment is called AUDS, which stands for anti-unmanned aerial vehicle defense system, and works against UAVs, or drones, by detecting, tracking, identifying, and defeating them, said Tom Scott, president of LITEYE Systems, who helped create AUDS.

According to Scott, the system works first by using the radar and camera to detect a drone. The radar feed comes from two 180-degree radars placed back-to-back in order to give the operators a 360-degree feed in real time. With the camera feed connected to the system, they are able to see what may be flying in their area. Once a drone has been identified on camera, operators put the target in their crosshairs and pull the trigger, which allows the system to lock on and track the target automatically.

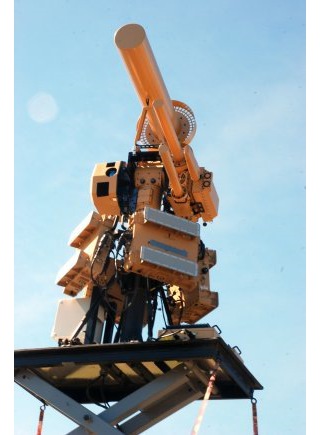

An anti-unmanned aerial vehicle defense system (AUDS) searches the skies of Fort Sill for UAVs on April 6 during the Maneuver Fires Integrated Experiment (MFIX). [Photo Credit: Monica K. Guthrie]

In the past, ground forces became familiar with counter improvised explosive device (IED) equipment designed to jam the signals to IEDs from individuals holding the detonation trigger. Today's counter UAV equipment is similar to those electric counter measures (Duke, Thor, and Warlock to name a few), only rather than defeating targets on the ground, they defeat airborne threats.

"The system then puts a 20-degree cone of energy downrange, and that will inhibit the drone and we can interrupt the signal from the operator to the drone," said Scott.

The 20-degree cone of energy allows the signal to be stronger because it is concentrated to a specific area rather than spread across the 180 or 360 degrees other systems utilize, said Scott. That stronger, more amplified signal produced by the AUDS is able to jam the signal between the UAV and the UAV's controller.

"The operator loses control of the drone," said Scott.

Soldiers from 108th Air Defense Artillery came from Fort Bragg, NC, to allow developers to see firsthand how Soldiers interacted with the system. Scott said he was pleased with how easily the Soldiers learned the AUDS and could now operate the system.

"It's been pretty awesome," said Pvt. Shamar Paulhill. "It's a pretty easy concept to grasp. We've only been out here for three days, and we already have it down. We are tracking, jamming stuff, and we brought down (many) drones," he said.

Paulhill and his battle buddy Pfc. Sergio Torres, both air missile defense crewmembers, explained how once they have acquired the target, they wait for instructions. If they jam the communication between the drone and the drone's operator, the drone could return to its home base, remain hovering, or fall from the sky.

While the AUDS is newer, Scott said their systems were rapidly deployed to units in October 2016. Scott said feedback came almost immediately.

"My guys operating the systems ... once they got it with the Soldiers and turned it on, the Soldiers called it 'the day the drones stopped'" said Scott.

Since October, two changes have already been implemented from the feedback Scott and his team have received from units using the AUDS. Now at MFIX, the goal is to integrate the system into the mobility part of the military, said Scott. The system currently is standalone with a generator to provide power.

"The deployment was done in a real hurry," said Scott. "Now we, as owners of the company, can sit back with the military and start to integrate this into other command-and-control and mobile systems."

-------------------------------------------------------------------------

Designfax Editor's Note: Range of effectiveness

-------------------------------------------------------------------------

By Mike Foley, Editor, Designfax

Kenneth Geyer, executive VP and co-founder of LITEYE Systems, told Designfax exclusively that the system in total has five different electronic attacks that focus on five different frequency bands.

"We force all class 1 and 2 UAVs to stop flying," said Geyer. "This includes all custom built."

"Depending on the type of UAV and which bands we utilize against them, they land in place, return home, or crash," Geyer said. "We control their electronics, and in some models we focus enough power on them to simply burn out their electronics."

The LITEYE Systems website fact sheet lists the radar range to be 8 km (just shy of 5 miles). But how far does the defeat capability extend?

"Our defeat ranges depend on the type (of system) we are using," Geyer said. "Some reach much further than others. While the exact ranges for each are also classified, our defeat abilities reach at least 2.5 km and some far beyond. This is why we focus our power downrange on the target and not in every direction."

"We don't believe in the omnidirectional jamming systems; they are wasting a ton of power trying to jam in every direction," he said. "This only allows them to be effective very close in. They also jam everything else in the area, along with the target. We choose to focus our power and have very little collateral interference on other systems."

Geyer also added that a return-to-home function is "a nice way to follow the UAV back to its operator."

"Remove the UAV that saves you now, follow it back to the pilot, and remove them," he said. "That stops tomorrow's attack."

Sources: U.S. Army, LITEYE Systems

Published April 2017

Rate this article

View our terms of use and privacy policy