|

| August 08, 2017 | Volume 13 Issue 30 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

What's a SLIC Pin®? Pin and cotter all in one!

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

Learn more.

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

Full-color 3D-printing Design Guide from Xometry

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

Get the Xometry guide.

Tech Tip: How to create high-quality STL files for 3D prints

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Read this detailed and informative Markforged blog.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

Engineer's Toolbox: How to pin a shaft and hub assembly properly

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

Read this very informative SPIROL article.

What's new in Creo Parametric 11.0?

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Read the full article.

What's so special about wave springs?

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

View the video.

New Standard Parts Handbook from JW Winco

JW Winco's printed Standard Parts Handbook is a comprehensive 2,184-page reference that supports designers and engineers with the largest selection of standard parts categorized into three main groups: operating, clamping, and machine parts. More than 75,000 standard parts can be found in this valuable resource, including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components.

JW Winco's printed Standard Parts Handbook is a comprehensive 2,184-page reference that supports designers and engineers with the largest selection of standard parts categorized into three main groups: operating, clamping, and machine parts. More than 75,000 standard parts can be found in this valuable resource, including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components.

Get your Standard Parts Handbook today.

Looking to save space in your designs?

Watch Smalley's quick explainer video to see how engineer Frank improved his product designs by switching from traditional coil springs to compact, efficient wave springs. Tasked with making his products smaller while keeping costs down, Frank found wave springs were the perfect solution.

Watch Smalley's quick explainer video to see how engineer Frank improved his product designs by switching from traditional coil springs to compact, efficient wave springs. Tasked with making his products smaller while keeping costs down, Frank found wave springs were the perfect solution.

View the video.

Top die casting design tips

You can improve the design and cost of your die cast parts with these top tips from Xometry's Joel Schadegg. Topics include: Fillets and Radii, Wall Thicknesses, Ribs and Metal Savers, Holes and Windows, Parting Lines, and more. Follow these recommendations so you have the highest chance of success with your project.

You can improve the design and cost of your die cast parts with these top tips from Xometry's Joel Schadegg. Topics include: Fillets and Radii, Wall Thicknesses, Ribs and Metal Savers, Holes and Windows, Parting Lines, and more. Follow these recommendations so you have the highest chance of success with your project.

Read the full Xometry article.

What's the latest from 3D Systems? Innovations for different industries, processes

3D Systems unveiled several new solutions at the RAPID+TCT 2025 show in April designed to change the way industries innovate. From new 3D printers and materials for high-mix, low-volume applications to marked improvements in how investment casting can be done, learn what is the state of the art from the original inventors of 3D printing.

3D Systems unveiled several new solutions at the RAPID+TCT 2025 show in April designed to change the way industries innovate. From new 3D printers and materials for high-mix, low-volume applications to marked improvements in how investment casting can be done, learn what is the state of the art from the original inventors of 3D printing.

Read the full article.

Clever! Indexing plungers with chamfered pins

JW Winco has developed a new type of indexing plunger -- GN 824 -- that can independently latch into edges and grooves. This is made possible by a chamfered plunger pin. When the chamfered pin encounters a raised latching geometry, it retracts and then springs back out again once it reaches the latching point. This new indexing plunger can be ordered with axial thread for fastening and a black plastic knob for operating the indexing plunger. In a clever design, the plunger pin can be adjusted by 360 degrees to ensure that it encounters the mating surface perpendicularly. This hardware is well suited for transport frames, mechanisms, or covers that need to be locked in place quickly and securely, especially without the need for manual intervention.

JW Winco has developed a new type of indexing plunger -- GN 824 -- that can independently latch into edges and grooves. This is made possible by a chamfered plunger pin. When the chamfered pin encounters a raised latching geometry, it retracts and then springs back out again once it reaches the latching point. This new indexing plunger can be ordered with axial thread for fastening and a black plastic knob for operating the indexing plunger. In a clever design, the plunger pin can be adjusted by 360 degrees to ensure that it encounters the mating surface perpendicularly. This hardware is well suited for transport frames, mechanisms, or covers that need to be locked in place quickly and securely, especially without the need for manual intervention.

Learn more.

UW team develops fast, cheap method to make supercapacitor electrodes for electric cars, high-powered lasers

Supercapacitors are an aptly named type of device that can store and deliver energy faster than conventional batteries. They are in high demand for applications including electric cars, wireless telecommunications, and high-powered lasers.

But to realize these applications, supercapacitors need better electrodes, which connect the supercapacitor to the devices that depend on their energy. These electrodes need to be both quicker and cheaper to make on a large scale and also able to charge and discharge their electrical load faster. A team of engineers at the University of Washington thinks they've come up with a process for manufacturing supercapacitor electrode materials that will meet these stringent industrial and usage demands.

The researchers, led by UW assistant professor of materials science and engineering Peter Pauzauskie, published a paper on July 17 in the journal Nature Microsystems and Nanoengineering describing their supercapacitor electrode and the fast, inexpensive way they made it. Their novel method starts with carbon-rich materials that have been dried into a low-density matrix called an aerogel. This aerogel on its own can act as a crude electrode, but Pauzauskie's team more than doubled its capacitance, which is its ability to store electric charge.

These inexpensive starting materials, coupled with a streamlined synthesis process, minimize two common barriers to industrial application: cost and speed.

"In industrial applications, time is money," said Pauzauskie. "We can make the starting materials for these electrodes in hours, rather than weeks. And that can significantly drive down the synthesis cost for making high-performance supercapacitor electrodes."

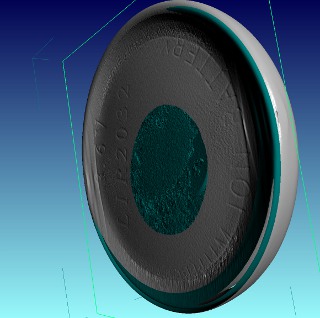

Full X-ray reconstruction of a coin cell supercapacitor.

Effective supercapacitor electrodes are synthesized from carbon-rich materials that also have a high surface area. The latter requirement is critical because of the unique way supercapacitors store electric charge. While a conventional battery stores electric charges via the chemical reactions occurring within it, a supercapacitor instead stores and separates positive and negative charges directly on its surface.

"Supercapacitors can act much faster than batteries because they are not limited by the speed of the reaction or byproducts that can form," said co-lead author Matthew Lim, a UW doctoral student in the Department of Materials Science & Engineering. "Supercapacitors can charge and discharge very quickly, which is why they're great at delivering these ‘pulses' of power."

"They have great applications in settings where a battery on its own is too slow," said fellow lead author Matthew Crane, a doctoral student in the UW Department of Chemical Engineering. "In moments where a battery is too slow to meet energy demands, a supercapacitor with a high-surface-area electrode could ‘kick' in quickly and make up for the energy deficit."

To get the high surface area for an efficient electrode, the team used aerogels. These are wet, gel-like substances that have gone through a special treatment of drying and heating to replace their liquid components with air or another gas. These methods preserve the gel's 3D structure, giving it a high surface area and extremely low density. It's like removing all the water out of Jell-O with no shrinking.

"One gram of aerogel contains about as much surface area as one football field," said Pauzauskie.

Crane made aerogels from a gel-like polymer, a material with repeating structural units, created from formaldehyde and other carbon-based molecules. This ensured that their device, like today's supercapacitor electrodes, would consist of carbon-rich materials.

Previously, Lim demonstrated that adding graphene -- which is a sheet of carbon just one atom thick -- to the gel imbued the resulting aerogel with supercapacitor properties. But Lim and Crane needed to improve the aerogel's performance, and make the synthesis process cheaper and easier.

In Lim's previous experiments, adding graphene hadn't improved the aerogel's capacitance. So they instead loaded aerogels with thin sheets of either molybdenum disulfide or tungsten disulfide. Both chemicals are used widely today in industrial lubricants.

The researchers treated both materials with high-frequency sound waves to break them up into thin sheets and incorporated them into the carbon-rich gel matrix. They could synthesize a fully loaded wet gel in less than two hours, while other methods would take many days. After obtaining the dried, low-density aerogel, they combined it with adhesives and another carbon-rich material to create an industrial "dough," which Lim could simply roll out to sheets just a few thousandths of an inch thick. They cut half-inch discs from the dough and assembled them into simple coin cell battery casings to test the material's effectiveness as a supercapacitor electrode.

Slice from X-ray computed tomography image of a supercapacitor coin cell assembled with the electrode materials. The thin layers -- just below the coin cell lid -- are layers of electrode materials and a separator. [Image: William Kuykendall]

Not only were their electrodes fast, simple, and easy to synthesize, but they also sported a capacitance at least 127 percent greater than the carbon-rich aerogel alone.

Lim and Crane expect that aerogels loaded with even thinner sheets of molybdenum disulfide or tungsten disulfide -- theirs were about 10 to 100 atoms thick -- would show an even better performance. But first, they wanted to show that loaded aerogels would be faster and cheaper to synthesize, a necessary step for industrial production. The fine-tuning comes next.

The team believes that these efforts can help advance science even outside the realm of supercapacitor electrodes. Their aerogel-suspended molybdenum disulfide might remain sufficiently stable to catalyze hydrogen production. And their method to trap materials quickly in aerogels could be applied to high-capacitance batteries or catalysis.

Co-author was doctoral student Xuezhe Zhou in the Department of Materials Science & Engineering. The research was conducted with the help of Energ2 Technologies, a UW start-up company based in Seattle that was recently acquired by BASF. The research was funded by the UW and the Clean Energy Institute. Pauzauskie is also affiliated with the Fundamental and Computational Sciences Directorate at the Pacific Northwest National Laboratory.

Source: University of Washington

Published August 2017

Rate this article

View our terms of use and privacy policy