|

| November 07, 2017 | Volume 13 Issue 41 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

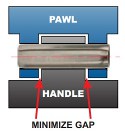

Superior fastening solution for securing rotating components to a shaft

Shaftloc® fasteners offer distinct advantages over other fastening methods when securing rotating components to a shaft. The key to this compact, efficient design is its asymmetric thread geometry that produces a greater clamping force -- outperforming other fastening methods. Shaftloc is a patented fastening system manufactured by SDP/SI.

Shaftloc® fasteners offer distinct advantages over other fastening methods when securing rotating components to a shaft. The key to this compact, efficient design is its asymmetric thread geometry that produces a greater clamping force -- outperforming other fastening methods. Shaftloc is a patented fastening system manufactured by SDP/SI.

Learn more.

Print 316L stainless steel on Markforged printers

316L Stainless Steel is now available for use with Markforged FX10 printers, allowing users to manufacture high-strength, accurate parts for demanding applications such as food and beverage processing, automotive, chemical and petrochemical processing, medical devices, and marine environments. This filament is safe and easy to handle. It makes machinable and polishable parts that have excellent corrosion resistance.

316L Stainless Steel is now available for use with Markforged FX10 printers, allowing users to manufacture high-strength, accurate parts for demanding applications such as food and beverage processing, automotive, chemical and petrochemical processing, medical devices, and marine environments. This filament is safe and easy to handle. It makes machinable and polishable parts that have excellent corrosion resistance.

Learn more.

10 best updates from the last 5 years: SOLIDWORKS

Follow along with the experts at TriMech Group as they chronicle the top feature updates in SOLIDWORKS. Are you still using SOLIDWORKS 2020 -- or an even older version? Find out what you are missing, such as: enhanced rendering and new technical drawing tools; improved file sharing, collaboration, and workflows; advanced customization and UI improvements; faster and more efficient assemblies and simulations; and more.

Follow along with the experts at TriMech Group as they chronicle the top feature updates in SOLIDWORKS. Are you still using SOLIDWORKS 2020 -- or an even older version? Find out what you are missing, such as: enhanced rendering and new technical drawing tools; improved file sharing, collaboration, and workflows; advanced customization and UI improvements; faster and more efficient assemblies and simulations; and more.

View the TriMech video.

Engineer's Toolbox: How to design the optimum hinge

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Read the full article.

Innovative new robo welding gun

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Learn more.

What's a SLIC Pin®? Pin and cotter all in one!

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

Learn more.

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

Full-color 3D-printing Design Guide from Xometry

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

Get the Xometry guide.

Tech Tip: How to create high-quality STL files for 3D prints

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Read this detailed and informative Markforged blog.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

Engineer's Toolbox: How to pin a shaft and hub assembly properly

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

Read this very informative SPIROL article.

What's new in Creo Parametric 11.0?

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Read the full article.

What's so special about wave springs?

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

View the video.

Forget those stitches and staples: Newly developed 'squirtable' elastic glue seals wounds in 60 seconds

Biomedical engineers from the University of Sydney in Australia and a number of universities in the United States have collaborated on the development of a potentially life-saving surgical glue called MeTro.

MeTro's high elasticity makes it ideal for sealing wounds in body tissues that continually expand and relax -- such as lungs, hearts, and arteries -- that are otherwise at risk of re-opening.

The MeTro biomedical glue is squirted directly onto the wound and activated with light.

The material also works on internal wounds that are often in hard-to-reach areas and have typically required staples or sutures due to surrounding body fluid, hampering the effectiveness of other sealants.

MeTro sets in just 60 seconds once treated with UV light, and the technology has a built-in degrading enzyme that can be modified to determine how long the sealant lasts -- from hours to months, in order to allow adequate time for the wound to heal.

The liquid or gel-like material has quickly and successfully sealed incisions in the arteries and lungs of rodents and the lungs of pigs, without the need for sutures and staples.

The results were published Oct. 5 in Science Translational Medicine, in a paper by the University of Sydney's Charles Perkins Center and Faculty of Science; Boston's Northeastern University, the Wyss Institute for Biologically Inspired Engineering at Harvard University, and the Beth Israel Deaconess Medical Center (BIDMC) in Boston.

MeTro combines the natural elastic protein technologies (developed in collaboration with author and University of Sydney McCaughey Chair in Biochemistry Professor Anthony Weiss) with light-sensitive molecules (developed in collaboration with author and Director of the Biomaterials Innovation Research Center at Harvard Medical School Professor Ali Khademhosseini). Elastin is the protein that gives blood vessels and skin their strength and flexibility.

Lead author of the study, Assistant Professor Nasim Annabi from the Department of Chemical Engineering at Northeastern University, oversaw the application of MeTro in a variety of clinical settings and conditions.

"The beauty of the MeTro formulation is that, as soon as it comes in contact with tissue surfaces, it solidifies into a gel-like phase without running away," said Annabi. "We then further stabilize it by curing it on-site with a short light-mediated crosslinking treatment. This allows the sealant to be very accurately placed and to tightly bond and interlock with structures on the tissue surface."

The University of Sydney's Professor Anthony Weiss described the process as resembling that of silicone sealants used around bathroom and kitchen tiles. "When you watch MeTro, you can see it act like a liquid, filling the gaps and conforming to the shape of the wound," he said. "It responds well biologically and interfaces closely with human tissue to promote healing. The gel is easily stored and can be squirted directly onto a wound or cavity."

VIDEO: Watch Professor Anthony Weiss demonstrate how the MeTro elastic surgical sealant works and potential applications.

The potential applications are powerful -- from treating serious internal wounds at emergency sites such as following car accidents and in war zones, as well as improving hospital surgeries, said Weiss.

Professor Khademhosseini from Harvard Medical School was optimistic about the study's findings.

"MeTro seems to remain stable over the period that wounds need to heal in demanding mechanical conditions, and later it degrades without any signs of toxicity; it checks off all the boxes of a highly versatile and efficient surgical sealant with potential also beyond pulmonary and vascular suture and stapleless applications," he said.

The next stage for the technology is clinical testing, Professor Weiss said.

"We have shown MeTro works in a range of different settings and solves problems other available sealants can't. We're now ready to transfer our research into testing on people. I hope MeTro will soon be used in the clinic, saving human lives."

A company called Elastagen Pty Ltd is commercializing the technology.

Source: University of Sydney

Published November 2017

Rate this article

View our terms of use and privacy policy