|

| January 08, 2019 | Volume 15 Issue 01 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox: How to design the optimum hinge

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Although many pin styles are available, Coiled Spring Pins are particularly well suited for

use in both friction- and free-fit hinges. To achieve optimum long-term hinge performance,

designers should observe these helpful design guidelines from SPIROL.

Read the full article.

Innovative new robo welding gun

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Comau's newest N-WG welding gun is designed for high-speed spot welding for traditional, hybrid, and electric vehicles, in addition to general industry sectors. It features a patented, single-body architecture that enables rapid reconfiguration between welding types and forces, and it delivers consistent performance across a broad range of applications, including steel and (soon) aluminum welding. It supports both X and C standard gun configurations, has fast arm exchange, and universal mounting options. It is fully compatible with major robot brands and represents a significant advancement in spot welding performance and cost efficiency.

Learn more.

What's a SLIC Pin®? Pin and cotter all in one!

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

The SLIC Pin (Self-Locking Implanted Cotter Pin) from Pivot Point is a pin and cotter all in one. This one-piece locking clevis pin is cost saving, fast, and secure. It functions as a quick locking pin wherever you need a fast-lock function. It features a spring-loaded plunger that functions as an easy insertion ramp. This revolutionary fastening pin is very popular and used successfully in a wide range of applications.

Learn more.

Engineering challenge: Which 3D-printed parts will fade?

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

How does prolonged exposure to intense UV light impact 3D-printed plastics? Will they fade? This is what Xometry's Director of Application Engineering, Greg Paulsen, set to find out. In this video, Paulsen performs comprehensive tests on samples manufactured using various additive processes, including FDM, SLS, SLA, PolyJet, DLS, and LSPc, to determine their UV resistance. Very informative. Some results may surprise you.

View the video.

Copper filament for 3D printing

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Virtual Foundry, the company that brought us 3D-printable lunar regolith simulant, says its popular Copper Filamet™ (not a typo) is "back in stock and ready for your next project." This material is compatible with any open-architecture FDM/FFF 3D printer. After sintering, final parts are 100% pure copper. Also available as pellets. The company says this is one of the easiest materials to print and sinter. New Porcelain Filamet™ available too.

Learn more and get all the specs.

Copper foam -- so many advantages

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Copper foam from Goodfellow combines the outstanding thermal conductivity of copper with the structural benefits of a metal foam. These features are of particular interest to design engineers working in the fields of medical products and devices, defense systems and manned flight, power generation, and the manufacture of semiconductor devices. This product has a true skeletal structure with no voids, inclusions, or entrapments. A perennial favorite of Designfax readers.

Learn more.

Full-color 3D-printing Design Guide from Xometry

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

With Xometry's PolyJet 3D-printing service, you can order full-color 3D prints easily. Their no-cost design guide will help you learn about different aspects of 3D printing colorful parts, how to create and add color to your models, and best practices to keep in mind when printing in full color. Learn how to take full advantage of the 600,000 unique colors available in this flexible additive process.

Get the Xometry guide.

Tech Tip: How to create high-quality STL files for 3D prints

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Have you ever 3D printed a part that had flat spots or faceted surfaces where smooth curves were supposed to be? You are not alone, and it's not your 3D printer's fault. According to Markforged, the culprit is likely a lack of resolution in the STL file used to create the part.

Read this detailed and informative Markforged blog.

Test your knowledge: High-temp adhesives

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Put your knowledge to the test by trying to answer these key questions on how to choose the right high-temperature-resistant adhesive. The technical experts from Master Bond cover critical information necessary for the selection process, including questions on glass transition temperature and service temperature range. Some of the answers may surprise even the savviest of engineers.

Take the quiz.

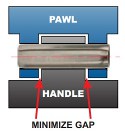

Engineer's Toolbox: How to pin a shaft and hub assembly properly

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

One of the primary benefits of using a coiled spring pin to affix a hub or gear to a shaft is the coiled pin's ability to prevent hole damage. Another is the coiled pin absorbs wider hole tolerances than any other press-fit pin. This translates to lower total manufacturing costs of the assembly. However, there are a few design guidelines that must be adhered to in order to achieve the maximum strength of the pinned system and prevent damage to the assembly.

Read this very informative SPIROL article.

What's new in Creo Parametric 11.0?

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Creo Parametric 11.0 is packed with productivity-enhancing updates, and sometimes the smallest changes make the biggest impact in your daily workflows. Mark Potrzebowski, Technical Training Engineer, Rand 3D, runs through the newest functionality -- from improved surface modeling tools to smarter file management and model tree navigation. Videos provide extra instruction.

Read the full article.

What's so special about wave springs?

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

Don't settle for ordinary springs. Opt for Rotor Clip wave springs. A wave spring is a type of flat wire compression spring characterized by its unique waveform-like structure. Unlike traditional coil springs, wave springs offer an innovative solution to complex engineering challenges, producing forces from bending, not torsion. Their standout feature lies in their ability to compress and expand efficiently while occupying up to 50% less axial space than traditional compression springs. Experience the difference Rotor Clip wave springs can make in your applications today!

View the video.

New Standard Parts Handbook from JW Winco

JW Winco's printed Standard Parts Handbook is a comprehensive 2,184-page reference that supports designers and engineers with the largest selection of standard parts categorized into three main groups: operating, clamping, and machine parts. More than 75,000 standard parts can be found in this valuable resource, including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components.

JW Winco's printed Standard Parts Handbook is a comprehensive 2,184-page reference that supports designers and engineers with the largest selection of standard parts categorized into three main groups: operating, clamping, and machine parts. More than 75,000 standard parts can be found in this valuable resource, including toggle clamps, shaft collars, concealed multiple-joint hinges, and hygienically designed components.

Get your Standard Parts Handbook today.

Looking to save space in your designs?

Watch Smalley's quick explainer video to see how engineer Frank improved his product designs by switching from traditional coil springs to compact, efficient wave springs. Tasked with making his products smaller while keeping costs down, Frank found wave springs were the perfect solution.

Watch Smalley's quick explainer video to see how engineer Frank improved his product designs by switching from traditional coil springs to compact, efficient wave springs. Tasked with making his products smaller while keeping costs down, Frank found wave springs were the perfect solution.

View the video.

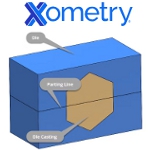

Top die casting design tips

You can improve the design and cost of your die cast parts with these top tips from Xometry's Joel Schadegg. Topics include: Fillets and Radii, Wall Thicknesses, Ribs and Metal Savers, Holes and Windows, Parting Lines, and more. Follow these recommendations so you have the highest chance of success with your project.

You can improve the design and cost of your die cast parts with these top tips from Xometry's Joel Schadegg. Topics include: Fillets and Radii, Wall Thicknesses, Ribs and Metal Savers, Holes and Windows, Parting Lines, and more. Follow these recommendations so you have the highest chance of success with your project.

Read the full Xometry article.

Hydrogen power in a bottle for on-the-go use: Army plans to license nanogalvanic aluminum powder discovery

The U.S. Army Research Laboratory's nanogalvanic aluminum powder for hydrogen generation. [U.S. Army photo by David McNally]

The U.S. Army Research Laboratory plans to license its discovery of a nanogalvanic aluminum powder for hydrogen generation.

Army researchers at Aberdeen Proving Ground in Maryland have developed a novel, structurally stable, aluminum-based nanogalvanic alloy powder that, when combined with water or any water-based liquid, reacts to produce on-demand hydrogen for power generation without a catalyst.

"This powder-based alloy includes material that disrupts the formation of an encapsulating aluminum oxide layer, allowing for the continuous production of hydrogen that can be used at the point of need to power a wide range of devices via fuel cells and internal combustion," said Dr. Anit Giri, a scientist with the lab's Weapons and Materials Research Directorate. "The powder can be easily manufactured to scale, and can be conveniently and safely transported via tablets or vacuum pouches, thus eliminating reliance on high-pressure hydrogen cylinders."

Dr. Anit Giri, a scientist with the U.S. Army Research Laboratory, observes a sample of a unique aluminum nanomaterial powder that reacts with water to produce hydrogen. [U.S. Army photo by David McNally]

ARL will be posting a Federal Register Notice and launching a supporting website inviting companies to submit their ideas on how best to commercialize this technology. The laboratory will then select the most appropriate partners and collaborators. Officials said license exclusivity will then be determined.

Researchers said the powders has many advantages, including:

- Energy and Power Source

- Stable Alloy Powder

- Non-Toxic

- Environmentally Friendly

- Hydrogen Emitting

- Manufacture to Scale

- Easily Transportable

Army researchers discovered the unique properties of the nanopowder while investigating aluminum alloy compositions for other purposes. The researchers, from the lab's Lightweight and Specialty Metals Branch, made the serendipitous discovery that at least one of these compositions can, in the presence of water, spontaneously generate hydrogen -- rapidly and efficiently.

"The researchers have since demonstrated rapid hydrogen generation rates using powder and tablet forms of the alloy," said Branch Chief Robert Dowding. "The hydrogen has been shown to be useful for powering fuel cells and is expected to power internal combustion engines." The researchers are currently taking advantage of the innovation by characterizing the hydrogen generation rates and purity of the gas generated, Dowding said.

Army researcher Anthony J. Roberts inflates a balloon with hydrogen produced from a chemical reaction between water and an aluminum nanomaterial powder discovered at the U.S. Army Research Laboratory at Aberdeen Proving Ground, Maryland. [U.S. Army photo by David McNally]

"They are also examining the effects of compositional changes to the alloy and systematic changes in the microstructure of the powders," he said.

Giri said the discovery has many benefits and applications, such as simple manufacturing.

"The powder can be made using current manufacturing techniques from either pure or alloyed aluminum," he said. "The manufacturing process is easily scalable and it is also very fast -- with a 75-percent theoretical hydrogen yield in one minute at standard temperature and pressure, and 100-percent theoretical yield in three minutes."

The nanopowder is also extremely efficient. Giri said 1 kg of powder can generate 4.4 kWh of energy -- enough to power 10 60-W incandescent light bulbs for more than seven hours or the equivalent LED bulbs for over 50 hours.

The material can be in powder or tablet form and be combined with any available water-based liquid to provide hydrogen on demand, at the point of need.

The discovery eliminates reliance on high-pressure cylinders, Giri said.

"It's easy to transport and store via tablets or vacuum-sealed pouches with no inherent inhalation risk," he said. "The powder is also environmentally friendly. Its by-products are stable and non-toxic. Finally, it's a versatile hydrogen source with direct combustion for vehicular power, to use in fuel cells to power any electronic device, and could potentially be used in 3D printing/additive manufacturing to create self-cannibalizing robots/drones."

In order to support a better understanding of the material, the laboratory established a website to showcase details on the technology and a review the process that will culminate in the granting of a patent license(s) around September 2018.

On this website, visitors can register their interest to be contacted about further developments, post general questions, and download background technical information, as well as templates for all the required documents that will be used throughout the process.

For further information, click here.

"The Federal Register announcement is a significant step forward in the transition of power to the Soldier in the field, where it will become available on demand at the point of need," Dowding said.

Source: U.S. Army Research Laboratory

Published July 2018

Rate this article

View our terms of use and privacy policy