|

| August 06, 2019 | Volume 15 Issue 29 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New smart motor controller for automotive

Toshiba has started sample shipments of the TB9M001FTG, the second product in its Smart Motor Control Driver (SmartMCD) series. This microcontroller can drive relays and control two brushed DC motors (forward and reverse control) in automotive applications. It incorporates a relay driver function and a LIN transceiver function, high-capacity flash memory, and power supply system. In addition to controlling brushed DC motors in applications such as power sunroofs, electric wipers, power windows, and power seats, it can also control sensors and actuators.

Toshiba has started sample shipments of the TB9M001FTG, the second product in its Smart Motor Control Driver (SmartMCD) series. This microcontroller can drive relays and control two brushed DC motors (forward and reverse control) in automotive applications. It incorporates a relay driver function and a LIN transceiver function, high-capacity flash memory, and power supply system. In addition to controlling brushed DC motors in applications such as power sunroofs, electric wipers, power windows, and power seats, it can also control sensors and actuators.

Learn more.

Versatile Transport System: Turbocharge conveyance

THK's Versatile Transport System is a high-mix production solution that will keep your production line moving. Its linear motor drive enables high-speed operations, and processing can be performed directly on top of the system's freely recirculating sliders. This highly precise, modular system has many unique features, including easily adjustable stop positions, flex layouts with path splitting and parallelization, and easy addition/subtraction of extension pieces.

THK's Versatile Transport System is a high-mix production solution that will keep your production line moving. Its linear motor drive enables high-speed operations, and processing can be performed directly on top of the system's freely recirculating sliders. This highly precise, modular system has many unique features, including easily adjustable stop positions, flex layouts with path splitting and parallelization, and easy addition/subtraction of extension pieces.

View the video.

Tech Tip: How to keep heavy loads balanced

Some Thomson smart linear actuators have a position-based synchro-nization option to help manage unbalanced loads when using multiple units. The system adjusts the speed of each actuator to keep them starting, moving, and stopping synchronously, regardless of their respective load distribution. So useful. So smart.

Some Thomson smart linear actuators have a position-based synchro-nization option to help manage unbalanced loads when using multiple units. The system adjusts the speed of each actuator to keep them starting, moving, and stopping synchronously, regardless of their respective load distribution. So useful. So smart.

Learn all about this feature.

Micropositioning stages ensure high accuracy

PI now offers fast delivery of the L-511 linear microposi-tioning stage, which is designed for applications requiring minimum incremental motion down to 20 nm and drive forces up to 22 lb. The L-511 can be combined to form XY or XYZ motion systems and integrated with rotary stages for enhanced flexibility. Features high-load recirculating ball bearings for exceptional durability, even under demanding, repetitive cycles. To enhance positioning accuracy and automation throughput, this stage integrates non-contact, direction-sensing optical reference point switches located at mid-travel.

PI now offers fast delivery of the L-511 linear microposi-tioning stage, which is designed for applications requiring minimum incremental motion down to 20 nm and drive forces up to 22 lb. The L-511 can be combined to form XY or XYZ motion systems and integrated with rotary stages for enhanced flexibility. Features high-load recirculating ball bearings for exceptional durability, even under demanding, repetitive cycles. To enhance positioning accuracy and automation throughput, this stage integrates non-contact, direction-sensing optical reference point switches located at mid-travel.

Learn more.

Robots think and act on the fly at moving assembly line speeds

Inbolt and FANUC are launching a manufacturing breakthrough enabling FANUC robots to tackle one of the most complex automation challenges: performing production tasks on continuously moving parts at line speeds. With Inbolt's AI-powered 3D vision, manufacturers can now automate screw insertion, bolt rundown, glue application, and other high-precision tasks on parts moving down the line without costly infrastructure investments or cycle time compromises.

Inbolt and FANUC are launching a manufacturing breakthrough enabling FANUC robots to tackle one of the most complex automation challenges: performing production tasks on continuously moving parts at line speeds. With Inbolt's AI-powered 3D vision, manufacturers can now automate screw insertion, bolt rundown, glue application, and other high-precision tasks on parts moving down the line without costly infrastructure investments or cycle time compromises.

Learn more.

Best high-speed rotary bearing in THK history

THK has developed its best-performing, high-speed rotary bearing ever: the High-Speed, Double-Row Angular Contact Ring BWH. This rotary bearing has balls aligned inside a cage between the inner and outer rings and is part of the THK Rotary Series, along with the cross-roller ring. The main features of this product are its ability to receive loads in all directions as well as its high rigidity and rotational accuracy, which are equal to that of cross-roller rings. By adopting a new structure to change the rolling elements from rollers to balls, this product achieves the greatest high-speed performance ever offered by THK.

THK has developed its best-performing, high-speed rotary bearing ever: the High-Speed, Double-Row Angular Contact Ring BWH. This rotary bearing has balls aligned inside a cage between the inner and outer rings and is part of the THK Rotary Series, along with the cross-roller ring. The main features of this product are its ability to receive loads in all directions as well as its high rigidity and rotational accuracy, which are equal to that of cross-roller rings. By adopting a new structure to change the rolling elements from rollers to balls, this product achieves the greatest high-speed performance ever offered by THK.

Learn more.

Elevating tables: Precise vertical positioning in tight spaces

As semicon-ductors and optical components become smaller and more sophisticated, the TZ Series of precision elevating tables from IKO International provides exceptional vertical positioning accuracy in a compact size. This unit features a unique wedge mechanism guided in the vertical direction by a pair of IKO C-Lube Super MX linear motion rolling guides arranged in parallel to achieve highly precise positioning with exceptional rigidity. An optional linear encoder provides full closed loop control to achieve positioning accuracy as high as 0.005 mm, with repeatability of +/-0.001 mm.

As semicon-ductors and optical components become smaller and more sophisticated, the TZ Series of precision elevating tables from IKO International provides exceptional vertical positioning accuracy in a compact size. This unit features a unique wedge mechanism guided in the vertical direction by a pair of IKO C-Lube Super MX linear motion rolling guides arranged in parallel to achieve highly precise positioning with exceptional rigidity. An optional linear encoder provides full closed loop control to achieve positioning accuracy as high as 0.005 mm, with repeatability of +/-0.001 mm.

Learn more and get all the specs.

This cobot is all about safety around people

The COBOTTA PRO from DENSO Robotics is a lightweight, high-speed collaborative robot designed for communication between workers and robots while maximizing productivity. It delivers a blend of productivity and safety for both simple tasks and multi-step processes like assembly and inspection work. The 6-axis unit operates at speeds up to 2,500 mm per sec when no workers are near and slows or stops when people approach. Two models available: PRO 900 (max payload 6 kg) and PRO 1300 (max payload 12 kg). Many more functions and features.

The COBOTTA PRO from DENSO Robotics is a lightweight, high-speed collaborative robot designed for communication between workers and robots while maximizing productivity. It delivers a blend of productivity and safety for both simple tasks and multi-step processes like assembly and inspection work. The 6-axis unit operates at speeds up to 2,500 mm per sec when no workers are near and slows or stops when people approach. Two models available: PRO 900 (max payload 6 kg) and PRO 1300 (max payload 12 kg). Many more functions and features.

Learn more.

Powerful, pull-type clapper solenoids handle myriad jobs

New powerful, low-profile, pull-type clapper solenoids are available from Magnetic Sensor Systems (MSS). Applications include valve control, locks, starters, ventilators, clamping, sorting, appliances, tools, HVAC, brakes, clutches, switches, mixing, fire suppression systems, door controls, detent latches, and more. The S-16-264 Series of 17 Pull-Type Clapper Solenoids have ampere turns (windings) adjusted to meet the specific force and duty cycle requirements of your application. They provide up to 130 lb (578 N) of force.

New powerful, low-profile, pull-type clapper solenoids are available from Magnetic Sensor Systems (MSS). Applications include valve control, locks, starters, ventilators, clamping, sorting, appliances, tools, HVAC, brakes, clutches, switches, mixing, fire suppression systems, door controls, detent latches, and more. The S-16-264 Series of 17 Pull-Type Clapper Solenoids have ampere turns (windings) adjusted to meet the specific force and duty cycle requirements of your application. They provide up to 130 lb (578 N) of force.

Get all the specs for these solenoids and other options.

Tech Tip: Belt, screw, or chain-driven actuator?

Bishop-Wisecarver provides a quick, very useful guide to help you evaluate the right drive strategy for your system: belt, screw, or chain-driven actuator. Each drive type has unique advantages and limitations, so evaluating all your options will help you find the most suitable actuator setup for your specific application needs.

Bishop-Wisecarver provides a quick, very useful guide to help you evaluate the right drive strategy for your system: belt, screw, or chain-driven actuator. Each drive type has unique advantages and limitations, so evaluating all your options will help you find the most suitable actuator setup for your specific application needs.

Read the Bishop-Wisecarver blog.

Ultra-precise linear stage -- down to 0.005 microns

PI, a global leader in precision motion control and nanoposi-tioning, now offers fast delivery of the L-511 linear micropositioning stage, which is designed for applications requiring minimum incremental motion down to 20 nm, drive forces up to 22 lb, and multi-axis configuration options. The L-511 can be combined to form XY or XYZ motion systems and integrated with rotary stages. A variety of drive and encoder options (stepper and servo motors, rotary, and linear encoders) enable ultra-fine sensitivity. Applications include: metrology, laser processing, semiconductors, biotech, optical alignment, and advanced automation.

PI, a global leader in precision motion control and nanoposi-tioning, now offers fast delivery of the L-511 linear micropositioning stage, which is designed for applications requiring minimum incremental motion down to 20 nm, drive forces up to 22 lb, and multi-axis configuration options. The L-511 can be combined to form XY or XYZ motion systems and integrated with rotary stages. A variety of drive and encoder options (stepper and servo motors, rotary, and linear encoders) enable ultra-fine sensitivity. Applications include: metrology, laser processing, semiconductors, biotech, optical alignment, and advanced automation.

Learn more and get all the specs.

Choosing the right stepper motor: PM or hybrid?

According to the experts at Lin Engineering, there are two primary types of stepper motors to consider: permanent magnet (PM) and hybrid. But which is right for your application? Both types have their advantages and disadvantages, and the choice ultimately depends on your specific requirements.

According to the experts at Lin Engineering, there are two primary types of stepper motors to consider: permanent magnet (PM) and hybrid. But which is right for your application? Both types have their advantages and disadvantages, and the choice ultimately depends on your specific requirements.

Read this informative Lin Engineering article.

New PTFE-free linear guide for precise positioning

The new drylin WWP linear guide from igus features a PTFE-free locking carriage. Engineered from lubrication-free, high-performance polymers and aluminum, the guide offers a lightweight, hygienic, and low-maintenance alternative to complex mechanical and electronic adjustment systems. It is significantly more compact and lightweight than conventional recirculating ball-bearing systems. Applications include interior components in vehicles, aircraft, and furniture.

The new drylin WWP linear guide from igus features a PTFE-free locking carriage. Engineered from lubrication-free, high-performance polymers and aluminum, the guide offers a lightweight, hygienic, and low-maintenance alternative to complex mechanical and electronic adjustment systems. It is significantly more compact and lightweight than conventional recirculating ball-bearing systems. Applications include interior components in vehicles, aircraft, and furniture.

Learn more and get all the specs.

Heavy-duty gear units for mixing and agitating systems

MAXXDRIVE industrial gear units from NORD DRIVE-SYSTEMS are an established drive solution for heavy-duty applications. In addition to conveying, lifting, and driving, they also play an important role in mixing and agitating systems. MAXXDRIVE units feature a compact, one-piece UNICASE housing that delivers long service life, easy maintenance, and quiet operation. Their robust design handles high axial and radial loads, achieves output torques up to 2,495,900 lb-in., and powers up to 8,075 hp.

MAXXDRIVE industrial gear units from NORD DRIVE-SYSTEMS are an established drive solution for heavy-duty applications. In addition to conveying, lifting, and driving, they also play an important role in mixing and agitating systems. MAXXDRIVE units feature a compact, one-piece UNICASE housing that delivers long service life, easy maintenance, and quiet operation. Their robust design handles high axial and radial loads, achieves output torques up to 2,495,900 lb-in., and powers up to 8,075 hp.

Learn more.

What are non-captive linear actuators?

According to PBC Linear, their new non-captive linear actuators are different from the more common external versions of lead screw-driven linear actuators because they allow the lead screw to completely pass through the motor. This fundamental difference offers advantages for designs that have limited space available or for engineers looking to shrink the overall size of their design package.

According to PBC Linear, their new non-captive linear actuators are different from the more common external versions of lead screw-driven linear actuators because they allow the lead screw to completely pass through the motor. This fundamental difference offers advantages for designs that have limited space available or for engineers looking to shrink the overall size of their design package.

Read the full PBC Linear blog.

Small but mighty: Mini plasma-powered satellite may launch new era in space exploration

By John Greenwald, Princeton Plasma Physics Laboratory

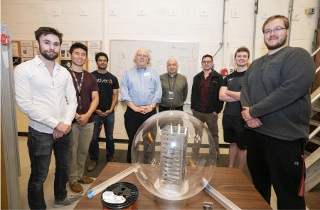

A tiny satellite under construction at the U.S. Department of Energy's (DOE) Princeton Plasma Physics Laboratory (PPPL) could open new horizons in space exploration. Princeton University students are building the device, called a cubic satellite, or CubeSat, as a testbed for a miniaturized rocket thruster with unique capabilities being developed at PPPL.

The thruster, whose development is led by PPPL physicist Yevgeny Raitses, holds the promise of increased flexibility for the mission of CubeSats, more than 1,000 of which have been launched by universities, research centers, and commercial interests around the world. The proposed propulsion device -- powered by plasma -- could raise and lower the orbits of CubeSats circling the Earth, a capability not broadly available to small spacecraft today, and would hold the potential for exploration of deep space. "Essentially, we will be able to use these miniature thrusters for many missions," Raitses said.

Princeton graduate and undergraduate students gather with advisors around a model of the CubeSat chassis inside a sphere. From left: Jacob Simmonds; Jerry Xiang; Nirbhav Chopra; Daniel Marlow, Evans Crawford 1911 Professor of Physics at Princeton; Yevgeny Raitses, PPPL physicist; Seth Freeman; Matthew Bledsoe; Daniel Piatek (Seton Hall student). [Photo by Elle Starkman/Office of Communications]

Hundreds of micropowered CubeSats

One example: Hundreds of such micropowered CubeSats are envisioned by physicist Masaaki Yamada, principal investigator of the PPPL Magnetic Reconnection Experiment (MRX), which studies magnetic reconnection -- the separation and explosive snapping together of magnetic field lines in plasma that triggers auroras, solar flares, and geomagnetic storms that can disrupt cell phone service and power grids on Earth. Such CubeSat fleets could capture in fine detail the reconnection process in the magnetosphere, the magnetic field that surrounds the Earth, Yamada said.

The miniaturized engine scales down a cylindrical thruster with a high volume-to-surface geometry developed at the PPPL Hall Thruster Experiment (HTX), which Raitses leads and launched with PPPL physicist Nat Fisch in 1999. The experiment investigates the use of plasma -- the state of matter composed of free-floating electrons and atomic nuclei, or ions -- for space propulsion.

Key advantage

A key advantage of the miniaturized cylindrical Hall thruster will be its ability to produce a higher density of rocket thrust than existing plasma thrusters used for most CubeSats now orbiting Earth. The miniaturized thruster can achieve both increased density and a high specific impulse -- the technical term for how efficiently a rocket burns fuel -- that will be many times greater than that produced by chemical rockets and cold-gas thrusters typically used on small satellites.

High specific-impulse thrusters use much less fuel and can lengthen satellite missions, making them more cost effective. Equally important is the fact that a high specific impulse can produce a large enough increase in a satellite's momentum to enable the spacecraft to change orbits -- a feature not available on currently orbiting CubeSats. Finally, high thrust density will enable satellites to accomplish complex fuel-optimized orbits in a reasonable time.

These capabilities provide many benefits. For example, a CubeSat might descend to lower orbit to track hurricanes or monitor shoreline changes and return to a higher orbit where the drag force on a satellite is weaker, requiring less fuel for propulsion.

The roughly foot-long CubeSat, which Princeton has dubbed a "TigerSat," consists of three nearly 4-in. aluminum cubes stacked vertically together. Sensors, batteries, radio equipment, and other instruments will fill the CubeSat, with a miniaturized thruster roughly equal in diameter to two U.S. quarters housed at either end. A thruster will fire to change orbits when the satellite passes the Earth's equator.

Mechanical and aerospace engineering students

Building the CubeSat are some 10 Princeton graduate and undergraduate students in the Department of Mechanical and Aerospace Engineering, with Daniel Marlow, the Evans Crawford 1911 Professor of Physics, serving as faculty advisor. Undergraduates include Andrew Redd, who leads design and construction of the CubeSat, and Seth Freeman, who is working full time on the project over the summer. Working on thruster development is Jacob Simmonds, a third-year graduate engineering student, whose thesis advisors are Raitses and Yamada. "This project began as a prototype of Yamada's CubeSat and has evolved into its own project as a testbed for the plasma thruster," Simmonds said.

Also under construction at PPPL is a test facility designed to simulate key aspects of the CubeSat's operation. Undergraduates working on their own time are building the satellite and this facility. "To the extent that students and their advisors have identified well-defined questions associated with the TigerSat project, they can get independent work credit," Marlow said. "Also, some problem sets in the introductory physics course for undergraduates that I teach have questions related to the TigerSat flight plan."

Simmonds, while working on the thruster, is drafting a proposal for NASA's Cubic Satellite Launch Initiative (CSLI) that is due in November. Projects selected by the initiative, which promotes public-private technology partnerships and low-cost technology development, have launch costs covered on commercial and NASA vehicles. Plans call for a TigerSat launch in the fall of 2021.

Value of collaboration

For Raitses, this project demonstrates the value of Princeton engineering students collaborating with PPPL and of University faculty cooperating with the Laboratory. "This is something that is mutually beneficial," he said, "and something that we want to encourage."

Support for the thruster work comes from Laboratory Directed Research and Development (LDRD) funds made available through the DOE Office of Science (FES). Basic science aspects of the novel thruster based on low-temperature magnetized plasma is supported by the Air Force Office of Scientific Research. Princeton University supports construction of the CubeSat and the test facility.

PPPL, on Princeton University's Forrestal Campus in Plainsboro, N.J., is devoted to creating new knowledge about the physics of plasmas -- ultra-hot, charged gases -- and to developing practical solutions for the creation of fusion energy. The Laboratory is managed by the University for the U.S. Department of Energy's Office of Science, which is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time.

Published August 2019

Rate this article

View our terms of use and privacy policy